(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- inCAD Library Home

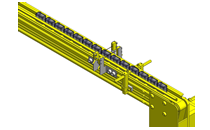

- > No.000184 Inspection Mechanism on Belt Conveyor

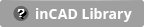

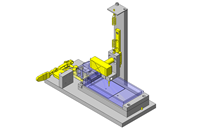

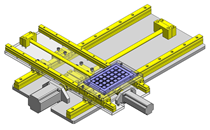

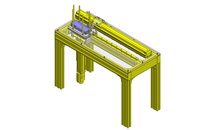

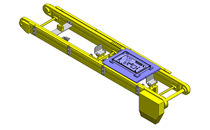

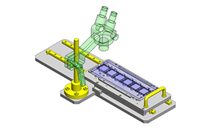

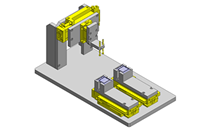

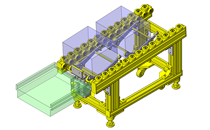

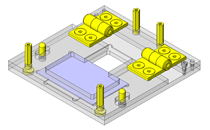

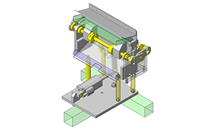

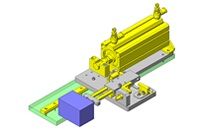

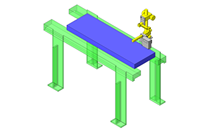

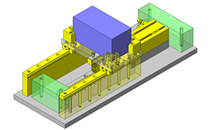

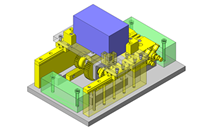

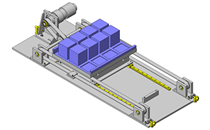

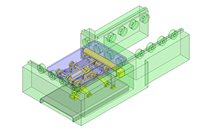

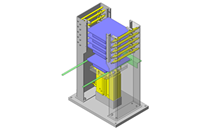

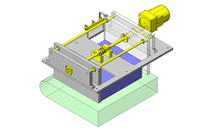

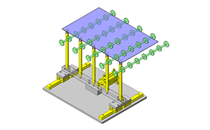

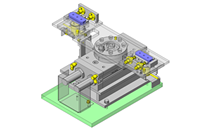

No.000184 Inspection Mechanism on Belt Conveyor

14

14

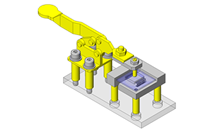

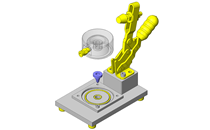

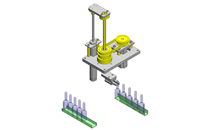

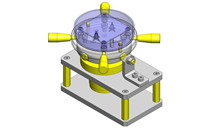

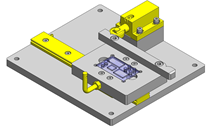

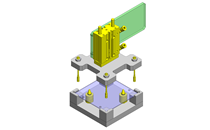

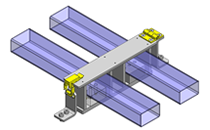

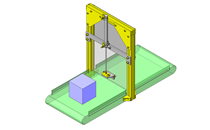

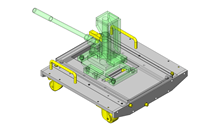

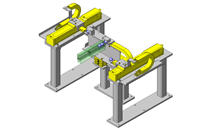

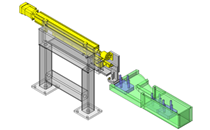

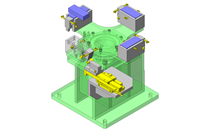

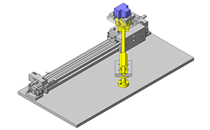

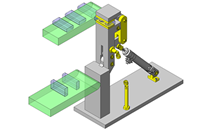

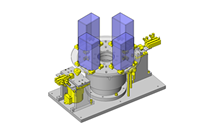

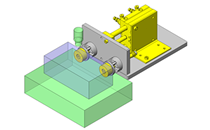

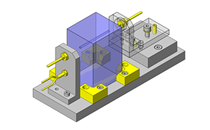

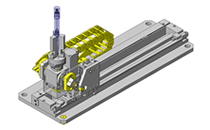

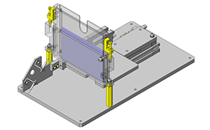

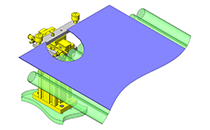

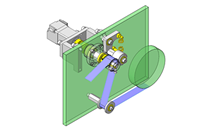

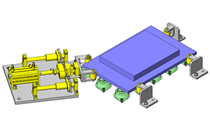

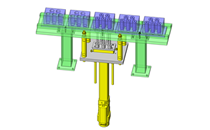

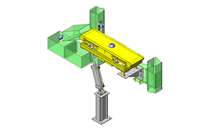

Work piece positioning and rotating mechanism.

Relevant category

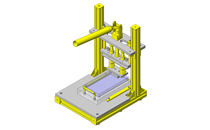

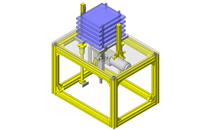

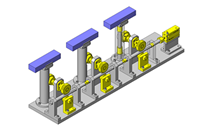

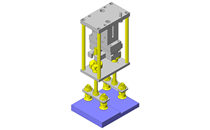

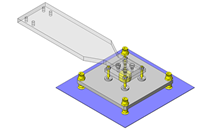

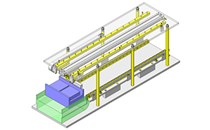

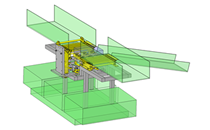

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

- Purpose

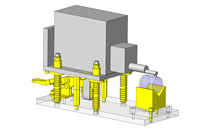

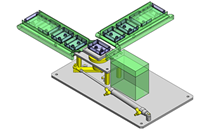

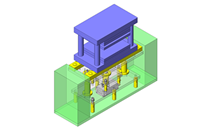

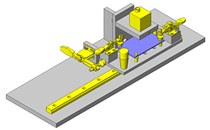

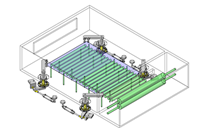

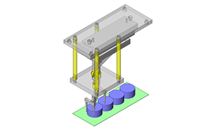

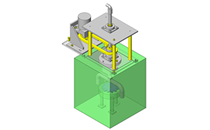

- To inspect defect on resin case.

- Operation

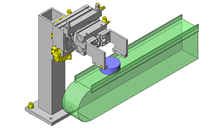

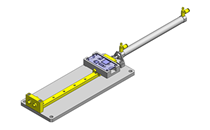

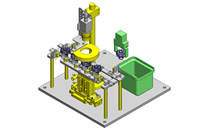

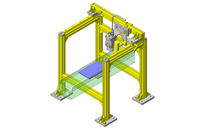

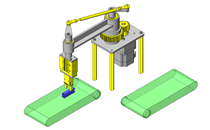

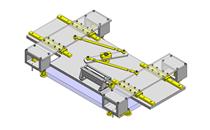

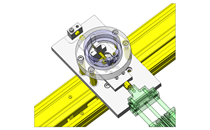

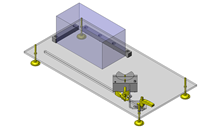

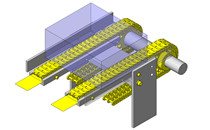

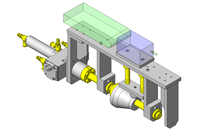

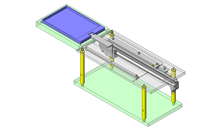

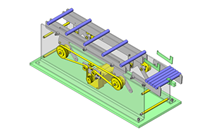

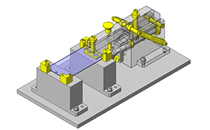

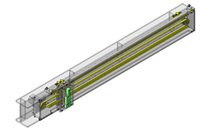

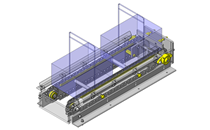

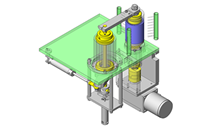

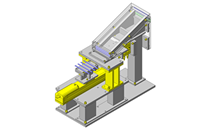

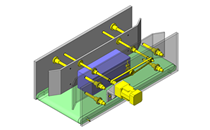

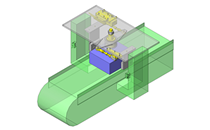

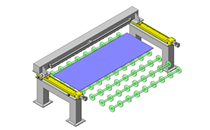

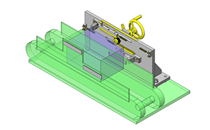

- To detect a work piece as it is transferred via a conveyor to a determined inspection position. Positioning is performed as a pusher presses a urethane roller against the drive roller. After positioning, the drive roller is rotated and the work piece appearance is conducted, After inspection, the pusher is retracted and the conveyor moves the workpiece from the inspection position.

Points for use

- Automated manufacturing line.

Target workpiece

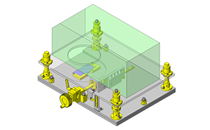

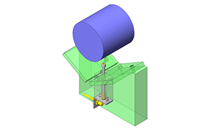

- Pallet

- Shape: cylindrical pallet

- Size: φ90 x H30mm

- Workpiece

- Shape: resin plate

- Size: W65xD8xH130mm

Design Specifications

Operating Conditions or Design Requirements

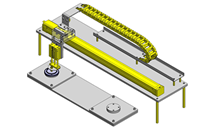

- Rotation speed during inspection: 12rpm

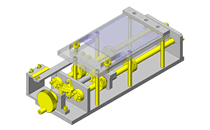

- Outer dimensions:W1032xD372xH183mm

Required Performance

- Positional repeatability:±0.5mm

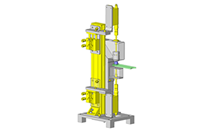

Selection Criteria for Main Components

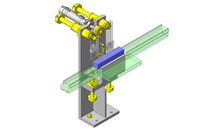

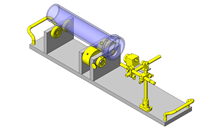

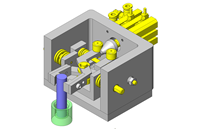

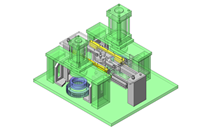

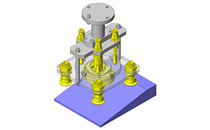

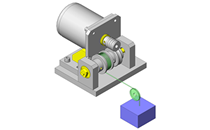

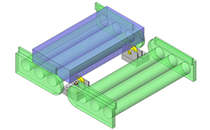

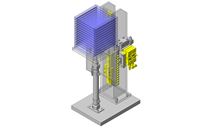

- Base on the required work piece rotational speed of 12rpm, a motor with a range of 280 to 2800rpm and a gear reduction ratio of 1/100 are selected.

Design Evaluation

Verification of main components

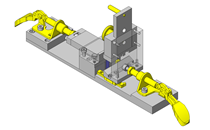

- Motor rotation speed, work piece rotation speed, cylindrical force, and overhang load are all verified.

- Conditional value: workpiece rotation speed N = 12rpm, motor rotation speed R = 280 to 2800rpm, motor output T0 = 0.005N·m,

gear head reduction ratio i = 1/100, gear head allowable overhang load Q0 = 620N·mm,

distance from motor mounting face to roller load position L = 17mm, robot cylinder maximum push force Fi = 44N,

friction coefficient μ = 0.6 (metal and rubber), workpiece diameter D1 = 90mm, drive roller diameter D2 = 50mm - If we put D1 as workpiece diameter, D2 as drive roller diameter, and N as workpiece rotation speed, and Q as gear head rotation speed,

N/Q = D2/D1, hence, Q = N x (D1/D2) = 12 x (90/50) = 21.6rpm - From rotation speed Q1 of gear head shaft with reduction ratio i: Q1 = R x i , Q1 = 2.8 to 28rpm

Therefore, the motor rotation speed satisfies the needs. - Motor torque T with reduction ratio i: T = T0 x i = 0.5N·m

As the motor torque and the drive roller torque are equal, if we put P as force at drive roller outer diameter,

T=P×(D2/2)

Hence, P = T x (2/D2) = 0.5 x {2/(50 x 10⁻³)} = 20N - From push force of robot cylinder applied to roller: F = Fi x μ, F = 44 x 0.6 = 26.4N

As F > P, the push force is suitable. - From allowable overhang load at load position: Q = Q0/L, Q = 620/17 = 36.5N

As Q > F, the overhang load is within the allowable range.

- Conditional value: workpiece rotation speed N = 12rpm, motor rotation speed R = 280 to 2800rpm, motor output T0 = 0.005N·m,

Other Design Consideration

- As a cylindrical work piece is positioned using two rollers, the accuracy of the conveyor does not need to be high.

- As the device does not use air pressure, an electric cylinder is used.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category

-

Relevant category