(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- inCAD Library Home

- > No.000126 Simplified Welding Mechanism

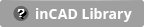

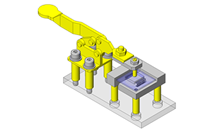

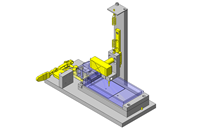

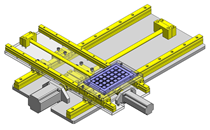

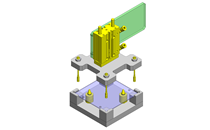

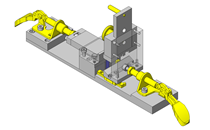

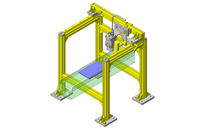

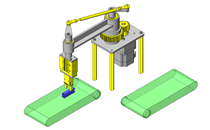

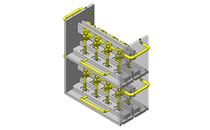

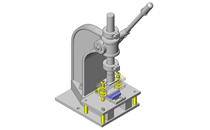

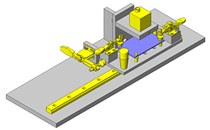

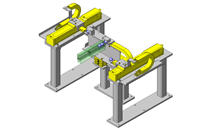

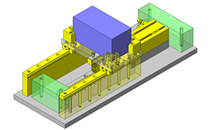

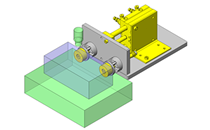

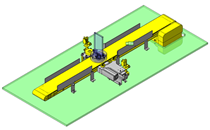

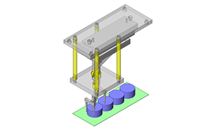

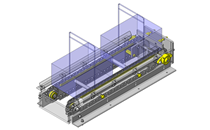

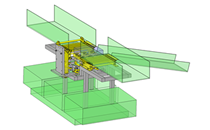

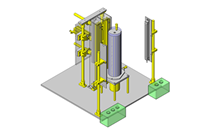

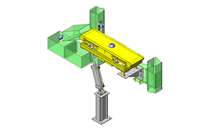

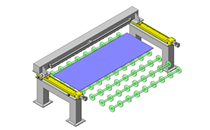

No.000126 Simplified Welding Mechanism

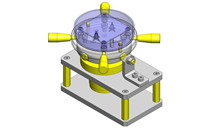

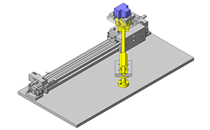

Welding mechanism utilizing a cylinder

Relevant category

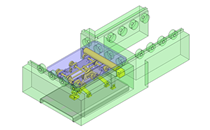

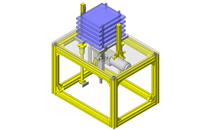

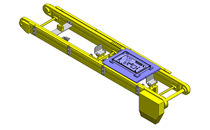

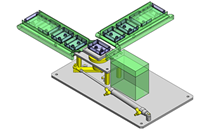

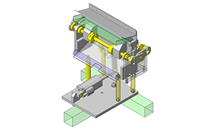

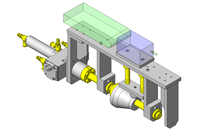

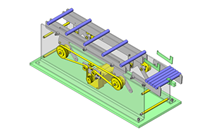

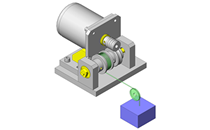

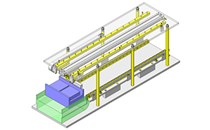

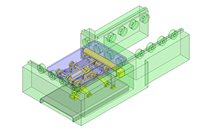

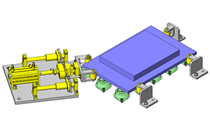

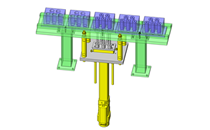

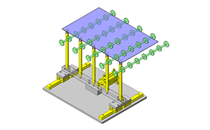

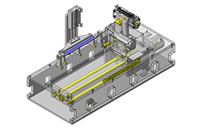

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

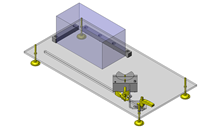

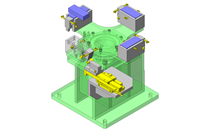

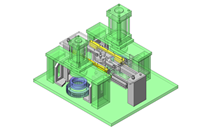

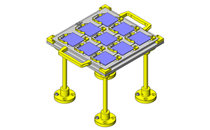

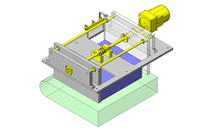

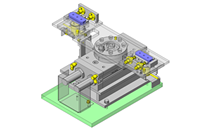

- Device capable of welding small size workpieces.

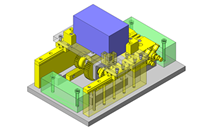

- Operation steps:

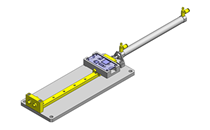

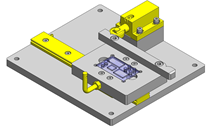

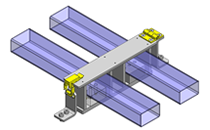

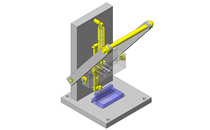

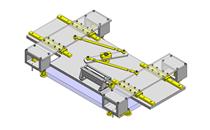

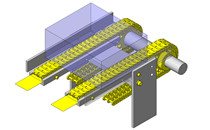

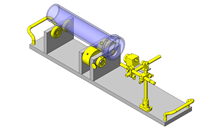

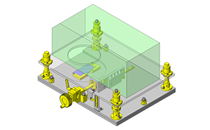

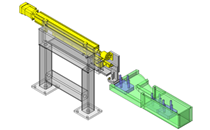

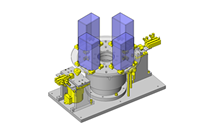

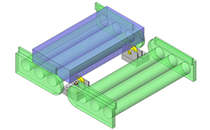

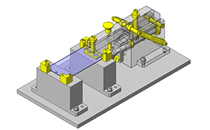

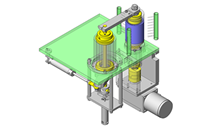

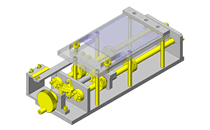

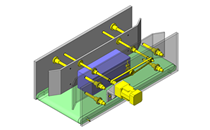

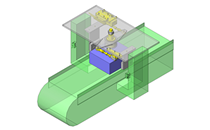

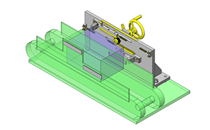

(1) Horizontal cylinder with a guide advances to clamp a workpiece.

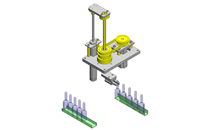

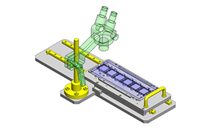

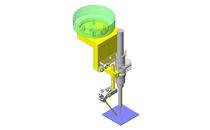

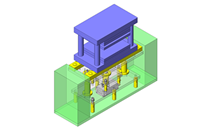

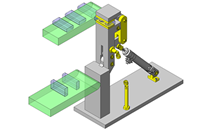

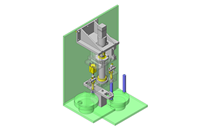

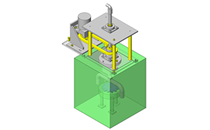

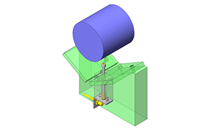

(2) Vertical cylinder with plate heaters descends.

(3) The plate heater welds workpieces 1 and 2.

(4) Vertical cylinder controlled by timer returns to start position.

(5) Clamp cylinder retracts.

Points for use

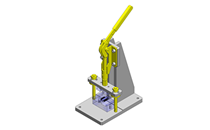

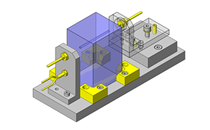

- An automatic mechanism in which the cylinder raises and lowers the heater and retains the workpiece during welding operation.

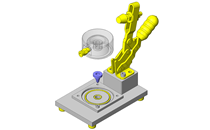

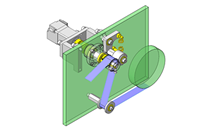

- Workpieces are manually inserted and removed by the worker using a dedicated tool (vacuum pad).

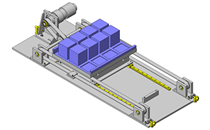

Target workpiece

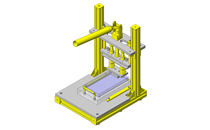

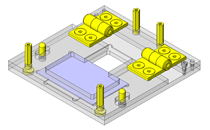

- Resin case outer dimensions: W40xD40xH6

- Film sheet outer dimensions: W36xD36xt0.5

Design Specifications

Operating Conditions or Design Requirements

- Outer dimensions: W350xD250xH325

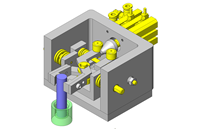

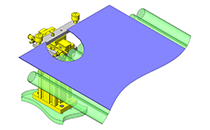

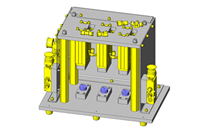

- Heat welding cylinder stroke: 74mm

- Workpiece retention cylinder stroke: 17mm

- Thrust of heat welding cylinder: 235.5N (from manufacturer's catalog)

Required Performance

- Heater power: 142W

Selection Criteria for Main Components

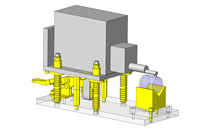

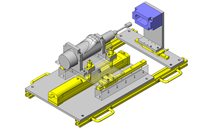

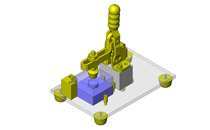

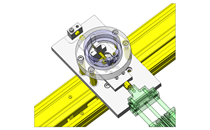

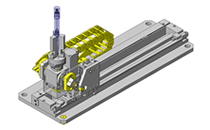

- Plate heater

- Select the size based on heat requirements to weld workpieces and the dimensions of the workpieces.

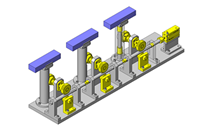

- Cylinder with a guide

- A cylinder with a guide that can withstand the allowable lateral load of 19N is selected.

Design Evaluation

Verification of main components

- Verify that the selected heater calorific value and cylinder allowable lateral load are sufficient for this application.

- Heat quantity required for the heater

- Mass of heated workpiece: 0.725kg (304 Stainless Steel)

- Specific heat of heated workpiece: 0.11kcal/kg°C

- Temperature rise: 230°C (heated until the temperature of the heated workpiece reaches 250°C)

- Heating time: 0.5 h (idling)

- Heating time: approx. 5sec (workpiece)

- The workpiece heating time should be determined through trial and error because it depends on the size, thickness, and material of the workpiece.

- Efficiency: 0.3

- Calculation formula: power for heater (kw) = mass of heated workpiece (kg) x specific heat of heated workpiece (kcal/kg°C) x temperature rise (°C)/(860 x heating time (h) x efficiency (η)) = 0.142 kW = 142W

- Cylinder with guide

- Weight of parts in moving unit: (0.0975kg + 0.0368kg) x 9.8 = 1.302N

Calculated value is below the allowable lateral load of the selected cylinder.

- Weight of parts in moving unit: (0.0975kg + 0.0368kg) x 9.8 = 1.302N

Other Design Consideration

- Welding time is controlled by a timer.

- A heat insulation material is used to prevent the heat of the heater from being transmitted to the upper and lower moving parts.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category

-

Relevant category