(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- inCAD Library Home

- > No.000233 Cleaning Chamber

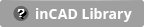

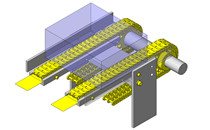

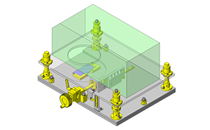

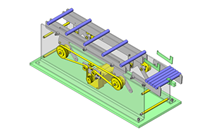

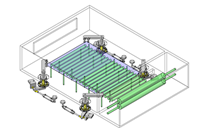

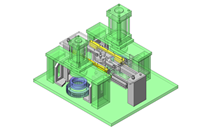

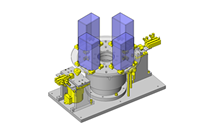

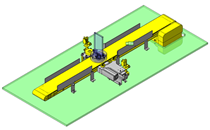

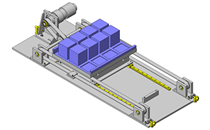

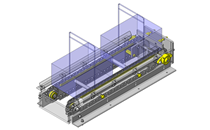

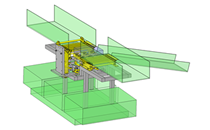

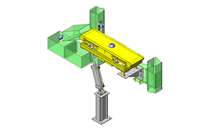

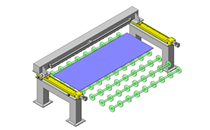

No.000233 Cleaning Chamber

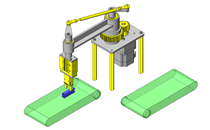

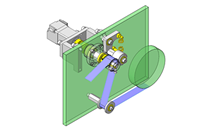

A set of nozzles are rotated to spray clean a workpiece.

Relevant category

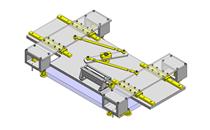

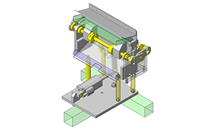

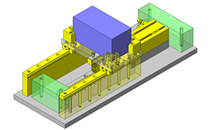

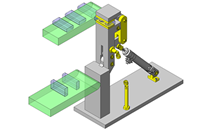

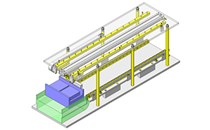

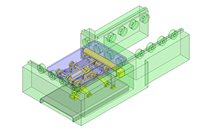

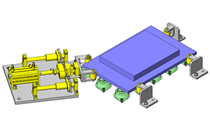

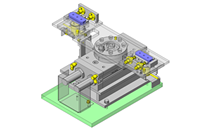

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

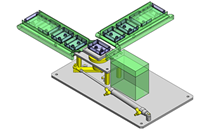

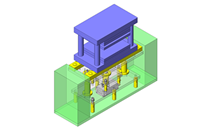

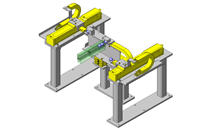

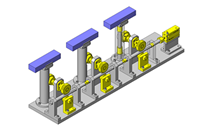

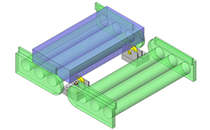

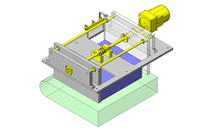

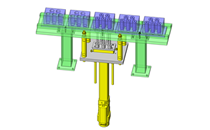

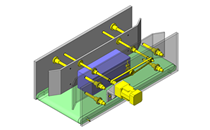

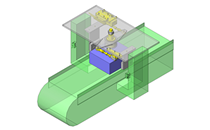

- Workpiece is cleaned by spraying cleaning solution from a set of rotating arm nozzles where the solution is flowed through the pipe rotating arms.

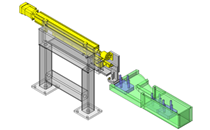

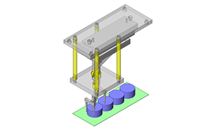

- A trap door is equipped for workpiece entry and exit.

Points for use

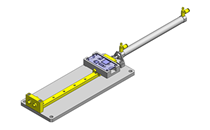

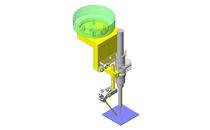

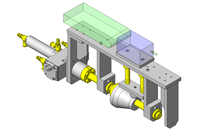

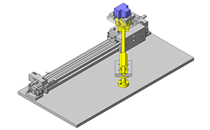

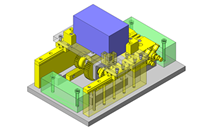

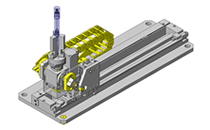

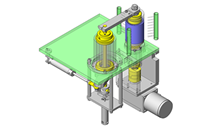

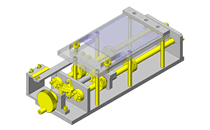

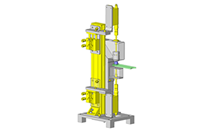

- Rotation is driven by belt, pulley, and motor.

Target workpiece

- Gear

- Exterior shape: φ120 x H 20mm

- Workpiece weight: 1kg

Design Specifications

Operating Conditions or Design Requirements

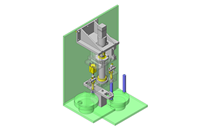

- External dimension: W 656 x D 300 x H 920mm

Motor - Capacity: 0.1kw

- Reduction Ratio: 1/40

- Torque: 19.6 N・m (60Hz)

- Rotation speed: 45 rpm (60Hz)

Required Performance

- Weight of rotating arm: 100N

- Flow rate per nozzle: 6(liter/min)

(currently, 12liter/min per 2 nozzles)

Selection Criteria for Main Components

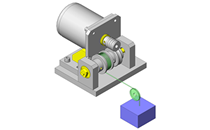

- Motor

- Motor that generates the required torque to rotate the arm is selected.

- Nozzle

- An even fan-shaped nozzle is selected for cleaning evenly.

Design Evaluation

Verification of main components

- The motor is selected so as to satisfy the load torque.

- Motor

- Condition value: Weight of rotating arm: 100N, safety margin ratio: 2, sprocket pitch circle diameter: 101.48mm

- Load torque of motor T = 1/2 x sprocket pitch circle diameter(m) x weight of rotating arm(N) x safety margin rate, thus,

T = 1/2 x 0.10148 x 100 x 2 = 10.1N・m < 19.6N・m (rated torque)

-> Select motor of 0.1kW

Other Design Consideration

- Select rotating arm that does not interfere with workpiece.

- Rotation speed is adjusted by adjusting the sprocket sizes.

- Water is used as the cleaning solution. Adjustment is made by changing pressure using regulator, etc.

- Door interlock is necessary for the trap door during cleaning.

- The tank is to be drained at the bottom after cleaning.

- Using stainless piping due to extensive exposure to potentially corrosive fluids.

Explore Similar Application Examples

Page

-

/

-

-

Relevant category