(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- inCAD Library Home

- > No.000100 Plastic Case Press-fit Fixture

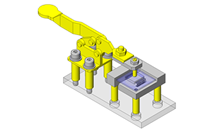

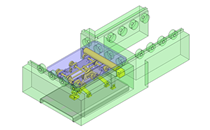

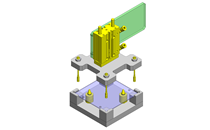

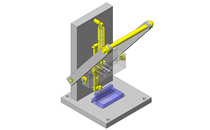

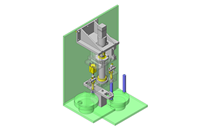

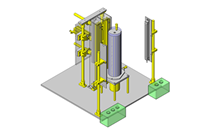

No.000100 Plastic Case Press-fit Fixture

Press-fitting fixture with 2 stage spring structure

Relevant category

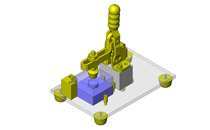

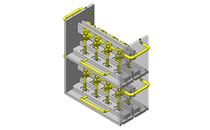

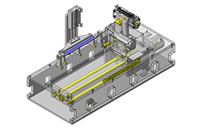

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

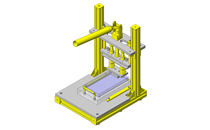

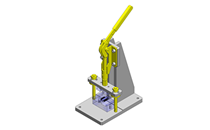

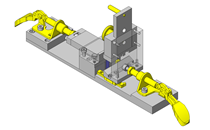

- Workpiece is press-fit with a rack press.

- The top spring is used to achieve the necessary press-fit load. The lower springs allow the stage to return.

Points for use

- This is a manual mechanism. It contains a two stage spring structure.

Target workpiece

- Plastic case

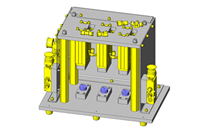

Dims.: W47 x D70 x H11 mm

Design Specifications

Operating Conditions or Design Requirements

- External dims.: W200 x D250 x H562 (Max.)mm

- Rack press max. stroke: 200mm

- Rack press output: 250kg

Required Performance

- Applied load: 58.8N

Selection Criteria for Main Components

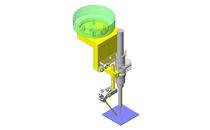

- Spring

- Select spring (spring constant) that has small displacement caused by plate and push plate weight.

Design Evaluation

Verification of main components

- Verify whether a spring can achieve necessary load.

- Spring load

- Applied load: Top stage spring - Lower stage spring = 176.4 - 117.6 = 58.8N

Formula: Reaction force F = kx

Assumed load: F = 176.4N (With 2 springs)

Assumed deflection when pressure applied: x = 6mm (no pre-compression->Set length=Free Length= 25mm, When stroked deflection=6mm)

Spring constant: k = 176.4 / 2 / 6 = 14.7N/mm is selected

Formula: Reaction force F = kx

Assumed load: F = 117.6N (With 2 springs)

Assumed deflection when pressure applied: x = 6mm (pre-compressed 1.36mm, Set length 28.64mm, Free length: 30mm, When stroked 4.64mm)

Spring constant: k = 117.6 / 2 / 6 = 9.8N/mm is selected

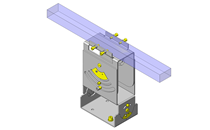

Plate + Push plate 2 weight: 3.5N ⇒ 0.36mm deflection

Other Design Consideration

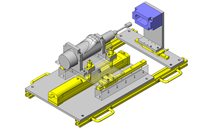

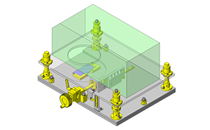

- Provide holes for anchors on the base to prevent moving when the rack press is operated.

- To allow for installation and removal of workpiece support base, provide openings for operator's hands.

- For the workpiece pallet, use locating pins for workpiece positioning.

- Contact surface of the rack press is lined with a stainless steel plate for wear and deformity prevention.

Explore Similar Application Examples

Page

-

/

-