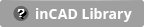

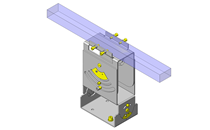

Miniature Linear Guide

| Product Name | Miniature Linear Guides Standard Blocks, Light Preload, Precision Class L Configurable Type |

| Part Number | SSEB10-95 |

| Features | The most basic type among all the industry standard-compliant blocks. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Compact size suitable for the fixture design

Back to page top

Available sizes

Miniature Linear Guide (Standard block / Light preload)

| Material | Hardness |

| Stainless steel (440C Stainless Steel) | 56HRC- |

| Carbon Steel (Alloy Steel including SCM) | 58HRC- |

■Sizes and Dimensions

| Number of Blocks | Block Width | Block Length | Overall Height | Rail Length |

| 1 | 17 | 23.6 | 8 | 40-130 |

| 20 | 30 | 10 | 35-275 |

| 27 | 33.9 | 13 | 45-470 |

| 32 | 42.4 | 16 | 70-670 |

| 40 | 50 | 20 | 100-700 |

| 2 | 17 | 23.6 x 2pcs. | 8 | 70-130 |

| 20 | 30 x 2pcs. | 10 | 95-275 |

| 27 | 33.9 x 2pcs. | 13 | 120-470 |

| 32 | 42.4 x 2pcs. | 16 | 150-670 |

| 40 | 50 x 2pcs. | 20 | 160-700 |

* Please see the product pages for details of selectable sizes.

Back to page top

Selection steps

■ Miniature Linear Guide Selection Steps

- Determine conditions of use

- (moving body mass, travel speed, motion pattern, life)

↓

- Selection of linear guide specifications

- (block height,overall height, rail length are

temporarily selected based on the conditions of use.).

↓

- Safety check

-

- Allowable load

- Life

- Preload

Back to page top

Accuracy Info

Preload and accuracy Standards

(μm)

| Radial clearance | -3~0 |

| Dimension tolerance of H | ±20 |

| Pair variation of H | 15 |

| Dimension tolerance of W2 | ±25 |

| Pair variation of W2 | 20 |

(μm)

| Rail length(mm) |

| -80 | 81-200 | 201-250 | 251-400 | 401-500 | 501-630 | 631-700 |

| Running parallelism | 3 | 7 | 9 | 11 | 12 | 13.5 | 14 |

Back to page top

Performance info.

Load rating of linear guides (Standard block ・Light preload ・High grade)

| Overall Height | Basic Load Rating | Allowable Static Moment |

| C (Dynamic) kN | C0 (Static) kN | MA

N・m | MB

N・m | Mc

N・m |

| 6 | 0.3 | 0.6 | 0.8 | 0.8 | 1.5 |

| 8 | 0.9 | 1.5 | 4.1 | 4.1 | 5.2 |

| 10 | 1.5 | 2.5 | 5.1 | 5.1 | 10.2 |

| 13 | 2.2 | 3.3 | 8.8 | 9.5 | 16.1 |

| 16 | 3.6 | 5.4 | 21.6 | 23.4 | 39.6 |

| 20 | 5.2 | 8.5 | 48.4 | 48.4 | 86.4 |

Back to page top

Technical calculations

Linear guide life calculations

- Operating Life

- When a Linear Guide is loaded and used in a linear reciprocating motion, scaly damage called flaking appear due to material fatigue as the stress works on the rolling elements and rolling contact surfaces constantly. Total travel distance until the first flaking occurs is called Life of Linear Guides.

- Rated life

- Rated life is the total travel distance that 90% of linear guides of the same type can reach, under the same conditions, with no occurrence of flaking damage. Rated life can be obtained from the Basic Dynamic Load Rating and the actual load applied on the linear bushings, as shown bellow.

-

- Load must be calculated before actually using Linear Guides. To obtain load during linear reciprocating motion, it is necessary to fully consider vibration and impact during motion, and also distribution status in relation to Linear Guides. So, it is not easy to obtain load calculation. All these conditions considered, the above-mentioned calculation formula is as follows.

-

- L: Rated life (km)

- fH: Hardness factor (see Fig-1)

- fT: Temperature factor (see Fig-2)

- fC: Contact factor (see Table-1)

- fW: Load factor (see Table-2)

- C: Basic dynamic load rating (N)

- P: Applicable load (N)

- ● Hardness Factor (fH)

-

For Linear Guide applications, sufficient hardness is required for ball contact shafts.Incorrect material hardness causes less allowable load, resulting in shorter life. Please correct the rated life according to the hardness factors.

- Temperature Factor (fT)

-

If the Linear Guide temperature exceeds 100°C, the Linear Guide and shaft hardness decreases, resulting in less allowable load and shorter life than used at a room temperature. Please correct the rated life according to the temperature factors.

* Please use linear guides under the allowable temperature range shown on each product page.

- Contact Factor (fC)

-

Table-1. Contact factor

Number of Linear Guide on One Shaft Contact Factor fc

| 1 | 1.00 |

| 2 | 0.81 |

| 3 | 0.72 |

| 4 | 0.66 |

| 5 | 0.61 |

In actual applications, 2 or more blocks per shaft are generally used. In this case, the load applied to each block varies depending on the precision of the machining, but is not uniformly distributed.

- Load Factor (fW)

-

Table-2. Load factor

| Condition of Use | fw |

No shocks/vibrations,

Low speed: 15 m/min. or less | 1.0-1.5 |

No significant shocks/vibrations,

medium speed: 60 m/min. or less | 1.5-20 |

With shocks/vibrations,

high speed: 60 m/min. or more | 2.0-3.5 |

To calculate load applied to the Linear Guides, in addition to object weight, it requires inertia force.However, it is difficult to obtain accurate calculations due to potential vibrations and impacts created during the reciprocating motion, beyond the normal start-stop motion.

- Applicable load calculation method

- When load is applied to a block, convert moment load into applied load using the following formula:

-

- P: Applied Load (N)

- F: Downward Load (N)

- C0: Static Load Rating (N)

- MA: Allowable Static Moment - Pitching Direction (N・m)

- MC: Allowable Static Moment - Rolling Direction (N・m)

- Lp: Load Point Distance (m) in Pitching Direction

- Lr: Load Point Distance (m) in Rolling Direction

Back to page top

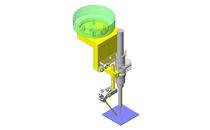

Spring Anchors

| Product name | Spring Anchors - Hexagonal |

| Part number | DSPO6-20 |

| Features | Posts for Tension Springs which can be mounted with a wrench. |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

A durable anchor that meets the dimension requirements for this design.

Back to page top

Available sizes

■Spring Anchors - Hexagonal

| Material | Surface Treatment |

| 1213 Carbon Steel | Black Oxide |

| Electroless Nickel Plating |

■Sizes and Dimensions

| Hex size | Mounting height

(Increments of 5 mm) | Screw Dia.

(Coarse) | Thread

Length | Spring Latch Shaft Dia. |

| 3 | 10-15 | M3 | 6 | φ1.8 |

| 4 | 10-20 | M4 | 8 | φ2 |

| 5 | 10-20 | M5 | 10 | φ3 |

| 6 | 10-25 | M6 | 12 | φ3.6 |

| 8 | 10-30 | M8 | 16 | φ5 |

| 10 | 15-30 | M10 | 20 | φ6 |

| 12 | 20-30 | M12 | 24 | φ6.5 |

*Please see the product pages for dimension details.

Back to page top

Urethane Molded Bearings

| Product name | Silicon Rubber / Urethane Molded Bearings - Flat |

| Part number | UMBB3-12 |

* Orange colored cells in the table below indicate the part numbers used in this example.

Selection criteria

Impact Resilient and operates quietly

Back to page top

Available sizes

■Urethane Molded Bearings - Flat, Shape A

| Tire Section | Bearing Material |

| Material | Hardness | Color | Steel

(52100 Bearing Steel) | Stainless Steel

(440C Stainless Steel) |

| Urethane | Shore A95 | Black | ○ | ○ |

| White | ○ | ○ |

| Shore A90 | Black | ○ | ○ |

| White | ○ | ○ |

| Shore A70 | Black | ○ | ○ |

| White | ○ | ○ |

| Shore A50 | Black | ○ | − |

| White | ○ | − |

| Anti-static Urethane | Shore A90 | Gray | ○ | − |

■Sizes and Dimensions

| I.D. | O.D. | Width | Bearing Used |

| φ3 | φ10 | 3 | W683ZZA |

| φ12 |

| φ4 | φ13 | 4 | W684AX50ZZ |

| φ16 | 5 | 624ZZ |

| φ5 | φ16 | WBC5−13ZZ |

| φ20 | 625ZZ |

| φ6 | φ20 | 696ZZ |

| φ28 | 6 | 626ZZ |

| φ8 | φ28 | 7 | 608ZZ |

| φ30 | 608ZZ |

| φ10 | φ30 | 8 | 6000ZZ |

| φ40 | 9 | 6200ZZ |

| φ15 | φ40 | 6002ZZ |

| φ45 | 11 | 6202ZZ |

| φ20 | φ45 | 9 | 6904ZZ |

| φ55 | 14 | 6204ZZ |

| φ25 | φ65 | 15 | 6205ZZ |

Back to page top

Performance info.

■Load Capacity of Urethane Molded Bearing - Flat

| O.D. | Allowable Load N |

| Shore A95 | Shore A90 | Shore A70 | Shore A50 |

| φ10 | 38 | 28 | 9 | 4 |

| φ12 | 53 | 34 | 10 | 6 |

| φ13 | 66 | 44 | 13 | 7 |

| φ16 | 79 | 59 | 16 | 6 |

| φ16 | 79 | 16 |

| φ20 | 102 | 78 | 20 | 9 |

| φ20 | 114 | 23 | 15 |

| φ28 | 218 | 157 | 44 | 39 |

| φ28 | 208 | 42 | 35 |

| φ30 | − | 176 | 81 | 65 |

| φ30 | 94 | 51 |

| φ40 | − | 274 | 136 | 93 |

| φ40 | 122 | 96 |

| φ45 | − | 343 | 109 | 102 |

| φ45 | 130 | 98 |

| φ55 | − | 490 | 225 | 176 |

| φ65 | − | 750 | 333 | 250 |

Back to page top

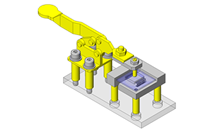

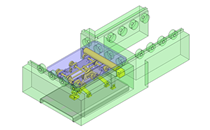

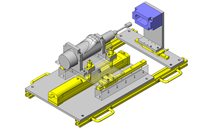

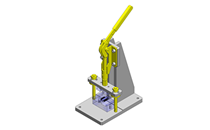

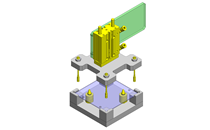

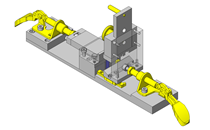

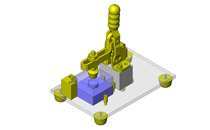

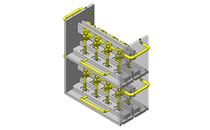

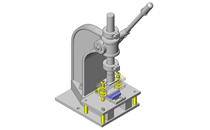

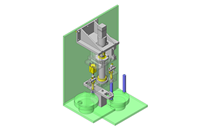

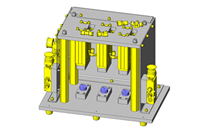

IDEA NOTE Press-fitting with lever action

The press-fitting anvil is retained with a tension spring and linear guide. A lever is used to operate the press-fitting anvil.

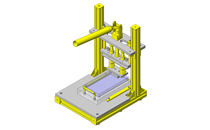

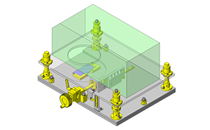

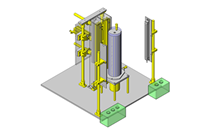

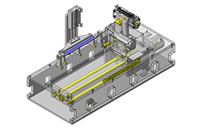

IDEA NOTE Adjusting Press-fitting stroke

Press-fitting stroke can be adjusted by using a stopper bolt.