(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- inCAD Library Home

- > No.000022 Long Stroke Slide Mechanism

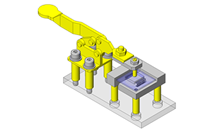

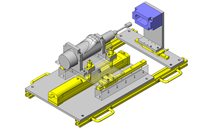

No.000022 Long Stroke Slide Mechanism

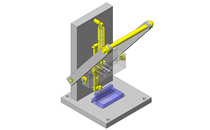

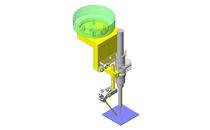

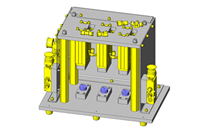

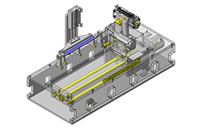

Manual long stroke slide mechanism

Relevant category

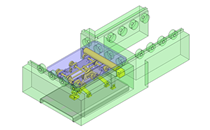

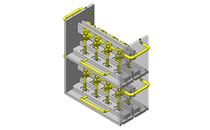

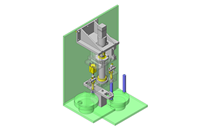

- * Unit assembly Data consists of some sub-assemblies.

It is configured so that each sub-assembly unit can be used as it is or edited.

Application Overview

Purpose

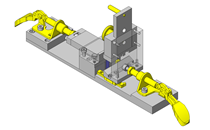

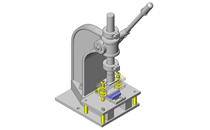

- Manual positioning slide carriage for bending resin rails.

Points for use

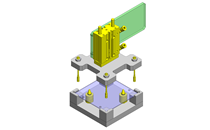

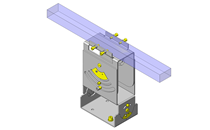

- Carriage is guided by cam followers that roll against a vertical sheet metal rail and a top/bottom support plate.

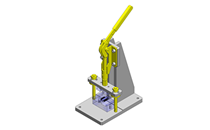

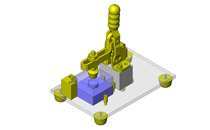

- Use lever handle to position the slide carriage.

- Stopper blocks located at the end of the guide rail are used to prevent the carriage from falling off.

Target workpiece

- Resin gasket and aluminum extrusions.

External dims.: Alum. Extrusion W850 x D20 x H20

Resin gasket: W850 x D8 x H6

Design Specifications

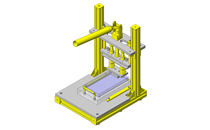

Operating Conditions or Design Requirements

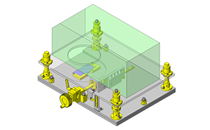

- Slide stroke: 900mm

External dims.: W1000 x D90 x H174

Required Performance

- Linear motion accuracy: ± 0.2mm

Selection Criteria for Main Components

- Cam follower

- For slide section adjustments standard type cam followers are used on the datum side, and eccentric cam followers on the adjustment side.

Design Evaluation

Other Design Consideration

- Without adding any stoppers slide carriage can slide thru entire length of guide rail.

- To accommodate arbitrary workpiece lengths, one side if workpiece is held against fixed retainer block while other side of workpiece is free. If concerned about workpiece shifting add extra retainers.

Explore Similar Application Examples

Page

-

/

-