(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Vacuum Pad Calculation Examples

- System configuration methods

- Workpiece weight calculations

- Vacuum pad theoretical holding power

- Selection of a vacuum pad

System configuration methods

Here, the procedure from theory to practice for configuring a vacuum system will be explained using an example.

This example uses the following workpiece and transfer system and is divided into 3 cases to be examined.

Workpiece

- Material:

- Steel plate (the state where they are stacked on pallets)

- Surface:

- Smooth, flat and dry

- Dimensions:

-

Maximum length 2,500mm

Maximum width 1,250mm

Maximum thickness 2.5mm

Weight approx. 60kg

Transfer system: Gantry (Gate type) transfer unit

- Compressed air:

- 0.8 MPa

- Control voltage:

- 24V DC

- Required work:

-

Horizontal Pick & Place

Lift 1 steel plate from the pallet, transfer it horizontally, and position it on the machining center.

- Maximum acceleration:

-

X, Y axis: 5 m/s2

Z axis: 5 m/s2

- Cycle time:

- 30 seconds

- Planned time:

-

Pickup: < 1 second

Release: < 1 second

Workpiece weight calculations

First, determine the workpiece weight (m). The workpiece weight is required for various calculations.

- m =

- L x B x H x ρ

- m =

- weight [kg]

- L =

- length [m]

- B =

- width [m]

- H =

- height [m]

- p =

- density [kg/m3]

In this example:

- m =

- 2.5m x 1.25m x 0.0025m x 7,850kg/m3

- m =

- 61.33kg

Vacuum pad theoretical holding power

The vacuum pad must be able to handle not only workpiece weight, but also the acceleration

force.

The safety factor should be at least 1.5 if the workpiece is smooth and does not have

breathability. The safety factor should be 2.0 or more for dangerous workpieces, breathable

workpieces, and workpieces with a rough or uneven surface. In addition, the safety factor of 2.0

or more shall be used when conditions such as acceleration and coefficient of friction are not

known or can’t be grasped accurately.

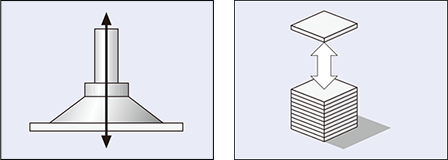

Case I:

When setting the vacuum pad horizontally and moving the workpiece in the vertical direction,

pick up the workpiece (in this example, a steel plate with dimensions of 2.5 × 1.25 m) from the pallet and lift it at an acceleration of 5 m/s2. There should be no horizontal movement.

Position the vacuum pad on the workpiece from the horizontal direction and lift the workpiece.

- FTH =

- m x (g + a) x S

- FTH =

- theoretical holding power [N]

- m =

- weight [kg]

- g:

- gravitational acceleration [9.81 m/s2]

- a =

- handling system acceleration [m/s2]

- S =

- safety factor (It should be at least 1.5. It should be 2.0 or more for dangerous workpieces, breathable workpieces, and workpieces with a rough or uneven surface)

In this example:

- FTH =

- 61.33kg x (9.81m/s2 + 5m/s2) x 1.5

- FTH =

- 1,363N

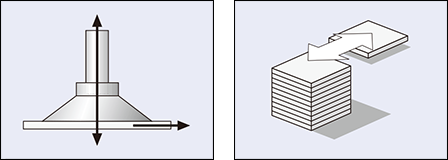

Case II:

When setting the vacuum pad horizontally and moving the workpiece in the horizontal

direction

lift the workpiece (steel plate with dimensions of 2.5 × 1.25 m) vertically and transport it horizontally. Acceleration is 5 m/s2.

Position the vacuum pad on the workpiece from the horizontal direction, and move the workpiece to the side.

- FTH =

- m x (g + a / μ) x S

- FTH =

- theoretical holding power [N]

- Fa =

- acceleration force = m × a

- m =

- weight [kg]

- g:

- gravitational acceleration [9.81 m/s2]

- a =

-

transport system acceleration [m/s2]

(Be cautious about workpiece release in an emergency)

- μ:

-

coefficient of friction

= 0.1 (surface to which oil adheres)

= 0.2 to 0.3 (wet surface)

= 0.5 (wood, metal, glass, stone, etc.)

= 0.6 (rough surface)

- S =

- safety factor (It should be at least 1.5. It should be 2.0 or more for dangerous workpieces, breathable workpieces, and workpieces with a rough or uneven surface)

In this example:

- FTH =

- 61.33kg x (9.81m/s2 + 5m/s2 / 0.5) x 1.5

- FTH =

- 1,822N

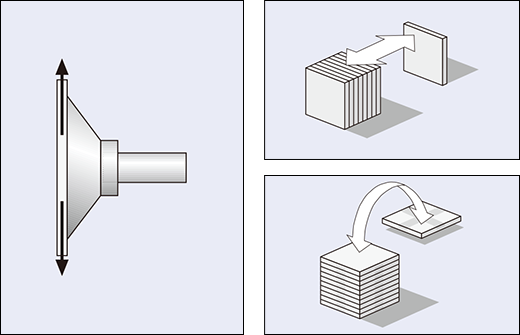

Case III:

When picking up the workpiece and moving the vacuum pad in the vertical direction,

pick up the workpiece (steel plate with dimensions of 2.5 × 1.25 m) from the pallet and move it at an acceleration of 5 m/s2 while rotating it.

- FTH =

- (m/μ) x (g+a) x S

- FTH =

- theoretical holding power [N]

- m =

- weight [kg]

- g:

- gravitational acceleration [9.81 m/s2]

- a =

-

transport system acceleration [m/s2]

(Be cautious about workpiece release in an emergency)

- μ:

-

coefficient of friction

= 0.1 (surface to which oil adheres)

= 0.2 to 0.3 (wet surface)

= 0.5 (wood, metal, glass, stone, etc.)

= 0.6 (rough surface)

- S =

- safety factor (It should be at least 1.5. It should be 2.0 or more for dangerous workpieces, breathable workpieces, and workpieces with a rough or uneven surface)

In this example:

- FTH =

- (61.33kg/0.5) x (9.81m/s2 + 5m/s2) x 2

- FTH =

- 3,633N

Comparison of cases I to III:

As shown in these examples, the required work is to lift the workpiece from a pallet, move it

laterally, and position it on a machining center. Accordingly, since there is no rotational

motion as in case III, only the case II needs to be considered.

In this case, the theoretical maximum holding power (FTH) is 1,822N. This force has

an effect on

the vacuum pad during horizontal transfer of the workpiece. Let’s proceed with a calculation

based on this value for a safe system configuration.

Selection of a vacuum pad

The theoretical holding power by calculation is the required force for the vacuum pad to safely transfer the workpiece.

Vacuum pad selected in this example:

Flat Vacuum Pad SAF (Nitrile rubber)

This vacuum pad is an excellent solution for cost-effectiveness when transporting smooth and flat workpieces.

In this case, it is necessary to decide whether the theoretical holding power based on calculations is carried by a piece of vacuum pad or divided by multiple vacuum pads.

For the steel plate (2,500 mm × 1,250 mm) as in these examples, normally 6 to 8 vacuum pads are used. The most important point that needs to be considered when determining the number of vacuum pads is that the steel plate does not bend during transport.

Calculation of holding force F S [N] required for 1 pc. of vacuum pad

- FS =

- FTH/n

- FS =

- holding force

- FTH =

- theoretical holding power

- n =

- number of vacuum pads

- In this example:

-

FS = 1,822N / 6

FS = 304N

The technical data for the Vacuum Pad SAF shows that, if 6 vacuum pads of this type are used, SAF100-M10-1.5 (100 mm in diameter, holding force of 430N) needs to be used.

- FS =

- 1,822N/8

- FS =

- 228N

The technical data for the Vacuum Pad SAF shows that, if 8 vacuum pads of this type are used, SAF80-M10-1.5 (80 mm in diameter, holding force of 272N) needs to be used.

Vacuum pad selected in this example:

Vacuum Pad SAF100-M10-1.5 (6 pcs.)

2.5mm thick steel plate can be lifted and transported with 6 vacuum pads.

Important:

The holding force of the vacuum pad must be larger than the calculated theoretical holding power.