(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- [Temporary Suspension of Order Acceptance for the Middle East] Due to suspension of air transport & courier services to the Middle East region, we regret to inform that we will temporarily stop accepting order(s) until further notice. Thank you for your understanding.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Toggle Mechanism (Fundamentals of Booster Mechanism)

This article is Part 5 in the Fundamentals Series. Could you move the earth using leverage? An introduction to booster mechanism with examples of how levers, toggles and crank mechanisms are used

- Boost mechanisms and lever mechanisms

- Toggle mechanism

- Usage example of booster mechanism

Booster Mechanism (2): Toggle Mechanism

A toggle mechanism is a type of link mechanism consisting of 2 links and a slider. The input causes the component to move in the input direction, and the output is increased by a booster mechanism.

Toggle mechanism

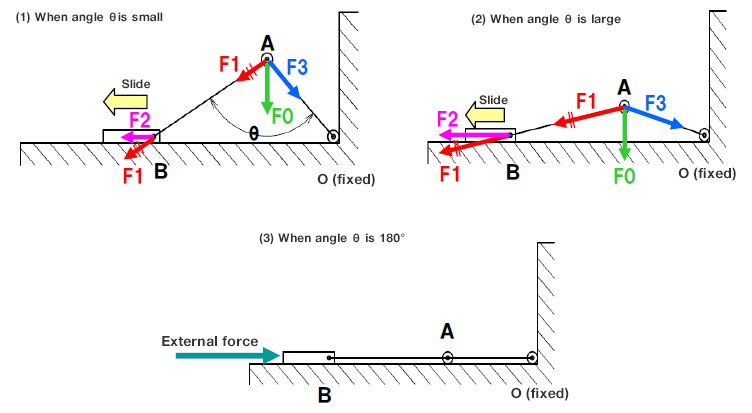

Fig. 2 Toggle mechanism

|

Fig. 2 illustrates the toggle mechanism in which joint O is fixed, and A is not fixed but free to move.

If the force acting vertically from joint A is F0, the horizontal force acting on B when F0 is applied is F2, and assuming that the lengths of joints OA and AB are the same,

is valid.

is valid.

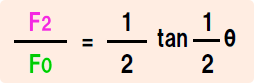

Because the tangent has the cycle shown in Figure 3 on the right, the force increases rapidly as the angle of θ/2 increases to 90°.

Thus, the closer OA and AB approach a straight line (180°), the more rapidly F2 increases.

Furthermore, when the angle θ/2 is 90°, the link becomes a straight line and the structure is very resistant to external forces even when the input is removed.

This toggle mechanism is applied to toggle clamps.

Fig. 3 Tangent graph

Application of toggle mechanism Toggle clamp

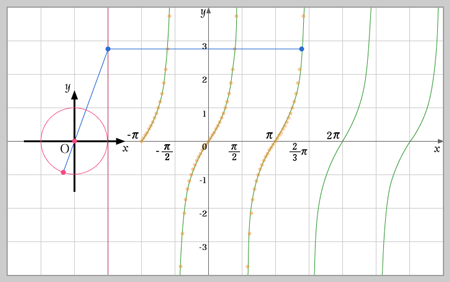

A toggle clamp is a jig that clamps objects using a toggle mechanism. Please refer to Fig. 4.

Fig. 4 consists of a 4-bar linkage with A and B fixed. BC and CD are the toggle mechanism, which means that link D operates on the input from link C. This movement causes the clamping pad to clamp the corresponding part.

When locked, link C enters slightly inside the line connecting BD and locks the clamped object. Therefore, when external force is applied, link C tries to move in the direction of the red arrow, but it cannot open because the direction is opposite to the opening.

To open, link C must be moved to the open side, and this mechanism generates a large clamping pressure at the time of locking.

Fig. 4 Toggle clamp mechanism

|

MISUMI toggle clamp

MISUMI offers toggle clamps of various shapes, including underside holding type (vertical/horizontal handle type) and horizontal drive orientation type.

Vertical type

Horizontal drive orientation type

Horizontal type

Level type

Long handle

Long arm

Forked type