(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed of our operating hours during the Chinese New Year Holidays. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Cam Followers and Roller Followers: Basic Knowledge and Proper Use (Fundamentals of Mechanical Components)

What Are Cam Followers and Roller Followers?

Conventionally, cam followers and roller followers have been used largely in cam mechanisms in automatic and dedicated machinery. More recently, they have been used as guide rollers in machine tools, printing machines, machine presses, transfer machines, and conveyors. Let us take a look at their respective features.

Cam Followers

A cam follower is a type of bearing with a highly rigid shaft that has a thick-walled outer ring and an internal roller known as a needle.

The needle works to enhance the rotational performance and can withstand high-speed rotations. Further, with a thicker outer ring than that of regular bearings, cam followers can be used in locations subject to impact loads and other loads.

Features

- 1. The shaft allows for simple installation

- 2. Ideal for use in locations subject to loads

- 3. Withstands high-speed rotations

Examples of Use

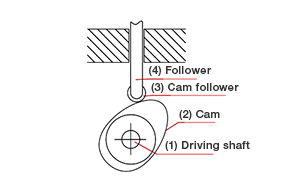

Example 1: Cam mechanism

The diagram shows a mechanism by which rotations of the cam and reciprocating follower are converted to linear motion and a single-action clamp mechanism.

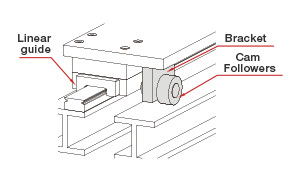

Example 2: Guide roller

Here the cam follower is used in place of a bearing.

The outer ring rotates in line with the linear motion of the linear guide.

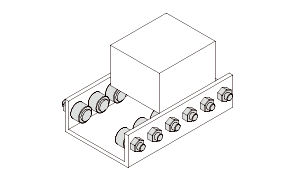

Example 3: Transfer roller

Here the cam follower is used as a transfer roller.

The outer ring rotates to carry goods.

Roller Followers

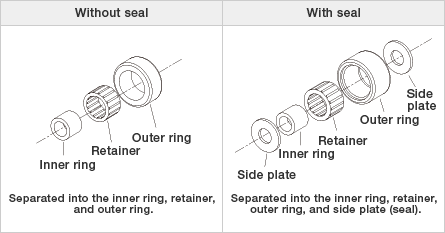

A roller follower is a highly rigid bearing with an internal roller known as a needle. Roller followers do not have shafts and thus allow for compact designs. As with cam followers, roller followers have a thick-walled outer ring, an inner ring, and a needle. As such, they can be used in locations subject to impact loads and locations that require high-speed rotations. As the length of the pins used to fix roller followers can be specified, there is no need to worry about the plate thickness of the counterpart.

Further, roller followers are largely divided into two types: separable types, in which the inner ring and outer ring can be separated, and non-separable types, in which the inner ring has been fixed with a side plate (seal). Roller followers come in various shapes and structures to cater to different uses.

Features

- 1. Ideal for use in small spaces

- 2. More resistant to load than rollers

- 3. Can be installed without worrying about counterpart plate thickness

Comparison of Separable Types and Non-separable Types

| Items compared | Separable type | Non-separable type |

|---|---|---|

| Bearing width tolerance | Large tolerance | Small tolerance |

| When external force is applied to the side plate | The side plate is unlikely to move | The side plate is likely to move |

| Use in U-shaped housing | ― | Favorable |

| Use when fixed with studs | Favorable | ― |

Examples of Use

Example 1: Transfer roller

To support pallets and steel sheets.

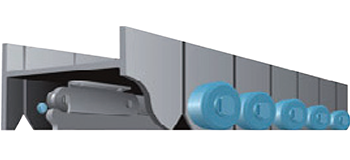

Example 2: Transfer roller

On both sides of slat conveyors.

Variations and Features

Diverse variations enable proper use in line with the desired application.

Cam Followers

| Application | General | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Features | Hex socket head type | Screwdriver type | ||||||||||

| Product description |

|

|

||||||||||

| Products of d3 to 10 have hex socket heads on the stud, while those of d12 to 20 have hex socket heads on both the stud and thread section. All types can be easily installed using a hex key. | These are cam followers with screwdriver heads on the stud. These are the standard types. | |||||||||||

| Shape | Crown type | Flat type | Crown type | Flat type | ||||||||

| Grease | General | Low dust gene-ration | Heavy duty | General | Low dust gene-ration | Heavy duty | General | Low dust gene-ration | General | Low dust gene-ration | ||

| Selection criteria | Direction of motion*1 | Linear motion | ○ | ○ | ○ | ◎ | ◎ | ◎ | ○ | ○ | ◎ | ◎ |

| Oscillating motion | ◎ | ◎ | ◎ | △ | △ | △ | ◎ | ◎ | △ | △ | ||

| Rotational speed*2 | Low-speed rotation | ◎ | ○ | ○ | ◎ | ○ | ○ | ◎ | ○ | ◎ | ○ | |

| High-speed rotation | ◎ | ○ | ○ | ◎ | ○ | ○ | ◎ | ○ | ◎ | ○ | ||

| Dust | Low dust generation | ○ | ◎ | ○ | ○ | ◎ | ○ | ○ | ◎ | ○ | ◎ | |

| Load*3 | Light duty | ◎ | ○ | ○ | ◎ | ○ | ○ | ◎ | ○ | ◎ | ○ | |

| Heavy duty | ○ | ○ | ◎ | ○ | ○ | ◎ | ○ | ○ | ○ | ○ | ||

| Application | Compact | Noise prevention | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Features | Precision type | Simple type | Resin type | Urethane type | ||||||

| Product description |

|

|

|

|

||||||

| These are small-diameter cam followers with extremely fine needles in the outer ring incorporated. They are ideally suited for use in electronic components and equipment, as well as office equipment. | These cam followers use ball bearings. They are well suited to the transfer of light duty goods and for use as guides. | In these types, resin has been press-fit into the cam follower. The resin absorbs shock in the counterpart and suppresses noise during rotation. | In these types, the cam follower has been coated in urethane. The urethane absorbs shock in the counterpart and suppresses noise during rotation. | |||||||

| Shape | Flat type | Flat type | R type | Flat Type | R type | Flat Type | ||||

| Grease | General | Low dust gene-ration | Heavy duty | General | General | General | General | General | ||

| Selection criteria | Direction of motion*1 | Linear motion | ◎ | ◎ | ◎ | ◎ | ○ | ◎ | ○ | ◎ |

| Oscillating motion | △ | △ | △ | △ | ◎ | △ | ◎ | △ | ||

| Rotational speed*2 | Low-speed rotation | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| High-speed rotation | ◎ | ○ | ○ | ◎ | × | × | △ | △ | ||

| Dust | Low dust generation | ○ | ◎ | ○ | ○ | ○ | ○ | ○ | ○ | |

| Load*3 | Light duty | ◎ | ○ | ○ | ◎ | ◎ | ◎ | ◎ | ◎ | |

| Heavy duty | △ | △ | ◎ | × | △ | △ | ○ | ○ | ||

The cam follower moves linearly across the flat surface of the counterpart

The cam follower moves in a curved line across the curved surface of the counterpart

*2

Please see the specification table on each product page for more detailed figures on rotational

speeds.

*3:

Please see the specification table on each product page for more detailed figures on loads.

Roller Followers

| Application | General | Noise prevention | Fixing pin | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Features | Separable type | Non-separable type | Urethane type | Roller follower pin | ||||||

| Product description |

|

|

|

|

||||||

| Separated into the inner ring, outer ring, and retainer. These are affordable options due to the simple structure. | These are non-separable roller followers on which side plates have been press-fit onto both sides of the inner ring. The manufacturer also offers heavy load types (crown) that can bear heavy loads. | These are non-separable roller followers coated with urethane, and are original MISUMI products. The urethane absorbs shock in the counterpart and suppresses noise during rotation. | These are original MISUMI roller follower pins. Please use them to fix roller followers in place. | |||||||

| Shape | Crown type | Flat type | Crown type | Heavy load crown type | R type | Flat type | - | |||

| Grease | General | Low dust generation | General | Low dust generation | General | General | General | - | ||

| Selection criteria | Direction of motion*1 | Linear motion | ○ | ◎ | ○ | ○ | ○ | ○ | ◎ | - |

| Oscillating motion | ◎ | △ | ◎ | ○ | ○ | ◎ | △ | |||

| Rotational speed*2 | Low-speed rotation | ◎ | ○ | ◎ | ○ | ○ | ◎ | ○ | ||

| High-speed rotation | ○ | ◎ | ○ | ○ | × | × | × | |||

| Dustv | Low dust generation | ○ | ◎ | ○ | ◎ | ○ | × | × | ||

| Load*3 | Light duty | ◎ | ○ | ◎ | ○ | ○ | ◎ | ○ | ||

| Heavy duty | ○ | ○ | ○ | ○ | ◎ | × | × | |||

The roller follower moves linearly across the flat surface of the counterpart

The roller follower moves in a curved line across the curved surface of the counterpart

*2

Please see the specification table on each product page for more detailed figures on rotational

speeds.

*3:

Please see the specification table on each product page for more detailed figures on loads.

User Feedback

In addition to their general use in cam mechanisms and for the transfer of goods, urethane-coated cam followers and roller followers are recently being used inside ATMs and printers. Urethane’s high coefficient of friction ensures the smooth movement of banknotes and printed material when they are transferred inside and released from machines.

There seem to be more applications of cam followers and roller followers.

We look forward to hearing about how you are using these followers in your

designs.