(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Guide for Cable Standards

Laws and regulations for cables include the Electrical Appliances and Materials Safety Act of Japan, Electricity Business Act, and Fire Service Act in Japan, and based on these laws and regulations, Japan national standards (JIS), the Japanese Cable Makers' Association Standard (JCS) and user standards (electrical power standards etc.) have been established.

As for non-Japanese standards, industrial standards have been established to set manufacture criteria for the quality of industrial products; therefore, attention is required for international trading.

Japanese Standards

1. Electrical Appliances and Materials Safety Act of Japan ("Denan-Ho")

The Old Electrical Appliance and Material Control Act of Japan was amended to become the Electrical Appliances and Materials Safety Act of Japan, which entered into force on April 1, 2001. The purpose of the Act is to regulate the manufacture, sale, etc. of electrical appliances and promote voluntary activities of private business operators’ ensuring the safety of electrical appliances to prevent risks and obstacles caused by electrical appliances.

The Category A electrical appliances and Category B electrical appliances under the Old Electrical Appliance and Material Control Act of Japan were discontinued and "Specified Electrical Appliances and Materials of Japan" and "Electrical Appliances Other Than the Specified Electrical Appliances and Materials" were defined in the new Act which requires manufacturers and importers to affix the PSE mark to their compliant products for sale so that consumers will be able to differentiate these products. Note that when it is structurally difficult to secure a marking space for part materials such as cables, fuses and wiring accessories, <PS>E or (PS)E can be used instead of the mark.

"Specified Electrical Appliances and Materials of Japan" and "Electrical Appliances Other Than the Specified Electrical Appliances and Materials" for cables

■ Specified Electrical Appliances and Materials of Japan

When it is difficult to secure a marking space

<PS>E

Any of the following cables (the rated voltage shall be between 100 V and 600 V inclusive)

-

(1) Any of the following insulated cables (the conductor’s nominal cross-sectional area shall not exceed 100 mm²):

- 1. Rubber insulated cable (including the ones whose insulator is made of synthetic rubber)

- 2. Synthetic resin insulated cable (excluding fluorescent cables and neon cables)

- (2) Cable (the conductor’s nominal cross-sectional area shall not exceed 22 mm², the number of wire core shall not exceed 7, and the rubber outer sheath shall be made of rubber (including synthetic rubber) or synthetic resin)

- (3) Cord

- (4) Flexible cable (the conductor’s nominal cross-sectional area shall not exceed 100 mm² and the number of wire core shall not exceed 7)

■ Electrical Appliances other than the Specified Electrical Appliances

When it is difficult to secure a marking space

(PS)E

-

(1) Any of the following insulated cables (the conductor’s nominal cross-sectional area shall not exceed 100 mm²):

- 1. Fluorescent cable

- 2. Neon cable

- (2) Cable (the rated voltage shall be between 100 V and 600 V, conductor’s nominal cross-sectional area shall be larger than 22 mm² and not exceed 100 mm², the number of wire core shall not exceed 7, and the rubber outer sheath shall be made of rubber (including synthetic rubber) or synthetic resin)

- (3) Heating cable

2. Japan Industrial Standards (JIS)

These national standards were established by the Japanese government based on the Industrial Standardization Act. The Industrial Standardization Act requires cables used in large quantity in industries and at households to be designated as commodity items by the competent minister (referred to as designated products) and products that passed the screening to have the JIS mark on them. The following 6 cable products are designated: Rubber cord, vinyl cord, 600 V indoor vinyl insulated cable (IV), outdoor weatherproof vinyl insulated cable (OW), drop vinyl insulated cable (DV), and 600 V vinyl insulated vinyl sheathed cable (VVR, VVF).

3. Japanese Cable Makers’ Association Standards (JCS)

These standards were established by the Japanese Cable Makers’ Association, an incorporated association for Japanese cable manufacturers. Its main standards include cable product standards and material standards, testing and inspection standards and technical calculation standards, while JCSs for cable-related products such as drums for cable packaging have been also established.

International Standards

1. CSA Standards (Canada)

(CANADIAN STANDARDS ASSOCIATION)

CSA is the abbreviated name of the Canadian Standards Association, which was founded as a not-for-profit standardization body in 1919 to establish standards for industrial products used in Canada and conduct safety testing subject to electrical appliances.

Most Canadian provinces require the sale of CSA-certified electrical appliances; therefore, all electrical appliances to be exported to Canada need to be CSA-certified and have the CSA mark on them.

For those products such as cables with small outer diameters on which printing the mark is difficult, they may mark "CSA" instead of the CSA mark.

2. IEC Standards

These standards were established by the International Electrotechnical Commission aiming to promote the international integration and harmonization of standards for electricity.

In relation to electricity, standards for bare wires (aluminum conductors), winding wires, power cables, communication cables, high-frequency cables, optical fibers, marine electrical equipment and the like have been established.

3. IEEE Standards

The Institute of Electrical and Electronics Engineers specifies matters about electrical equipment instruments, machines, electronic parts and computers and so on.

4. EIA Standards

The Electronic Industries Association established standards for electronic equipment and parts for general households and for industrial use. They include electron tubes, recording audio equipment, communication equipment, semiconductors. The standards are indicated as RS standards and EIA/TIA standards. The renowned are standards for interfaces such as RS232 and 422.

5. MIL Standards

These standards were established by the US Department of Defense for the purpose of standardizing specifications of materials, products, and services used by federal government institutions and used for industrial purposes.

6. NEMA Standards

These are group standards established by the National Electrical Manufacturers Association in the US for the purpose of providing guidelines for selection and purchase of electrical appliances. Among its cable-related standards, standards for winding wires are widely recognized across countries.

7. UL Standards (US)

(UNDERWRITERS LABORATORIES INC.)

UL is a nonprofit testing organization founded by a fire underwriter group in the US in 1894. UL develops safety standards not only for electrical appliances but for products in various fields from daily life appliances to commercial and industrial appliances such as life jackets, recreational boats, lawn mowers, garage door shutters and also conducts safety research on those products.

Passed products are listed as certified products by category specified by UL and publicly disclosed. Therefore, this list is an important source of information for users when they select products.

For electrical appliances, 2 lists are released: a list of unconditionally-certified products called "Listing" (Green Book) mainly applied to equipment and a list of conditionally-certified products called "Recognition" (Yellow Book) applied to parts, etc. used for equipment.

In the US, many municipalities require the use of UL-certified products by state laws, city by-laws and the like.

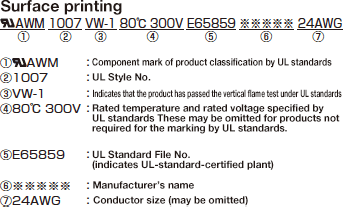

Marking for UL-certified cables

UL standards-compliant products are given an indication marking on their surfaces that indicates specified information. However, products on which printing is difficult such as fluoropolymer and cables with small outer diameter may not be marked.

Explanation of abbreviations and terms used by UL and CSA

| A. W. M | Abbreviation of Appliance Wiring Material |

|---|---|

| TR-64, TR-32, TEW, REW |

T: Thermoplastic or insulation R: Radio Circuit Wire EW: Equipment Wire -64: The thickness of the insulator, nominal 1/64 inches. -32: The thickness of the insulator, nominal 1/32 inches. |

UL Style No.

| Style No.1000s and 10000s e.g. Style 1007, 1015, etc. |

Single-core wires and cables |

|---|---|

| Style No. 2000s and 20000s e.g. Style 2464, 20276, etc. |

Wires and cables having 2 or more cores |

| Style No. 3000s | Wires and cables structured with special insulating materials |

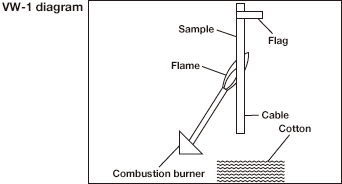

VW-1

VW-1 is the abbreviation of Vertical Wire, meaning the vertical flame test under UL standards. The test is conducted by using a gas burner to heat for 15 seconds a sample which is kept vertical, and then, turning the burner flame off for 15 seconds, which is repeated 5 times. To pass the test, the flame must burn out within 60 seconds after any time the burner is turned off during the 5 times. In addition, the flag attached at the top of the sample and the cottons at the bottom must not be burned while the sequence is being repeated 5 times. Only those cables that have passed the test are determined to have the required flame retardancy and marked with "VW-1."

8. CCC Standards (China)

As China joined the WTO, former CCIB certification (for import) and CCEE certification (for sale) were consolidated, which was partially implemented on May 1, 2002. The China Compulsory Certification (CCC) is operated by and CCC approvals are made by the General Administration of Quality Supervision, Inspection and Quarantine (AQSIQ) and the Certification and Accreditation Administration of the People's Republic of China (CNCA). Starting on May 1, 2003, importing into or selling in China those products not having the CCC mark has been prohibited. Whether or not a system is subject to CCC, the parts fitted into the system are not required to be CCC-certified per part. (For details, please consult a testing institution.) As of November 2008, 172 commodity items in 23 categories are subject to CCC. Based on the fact that the scope is expanding from electronic and electrical products to toys and information security products, the scope of CCC application is expected to expand further.

European Standards Overview

Starting on January 1, 1995, exporting to or selling in Europe machines without the CE marking has been restricted. EC Machinery Directives (89/392/EEC and 93/42/EEC) specify safety and technical standards for machines and these technical requirements must be met for a machine to have the CE marking. However, the EC Machinery Directive only covers general criteria and the least matters with which machines must comply; therefore, different European Standards need to be considered for other electricity-related matters such as electric power supply and electric control. Due to the EC integration, safety standards in the member states in Europe are being integrated as European Norm (EN) or European Standards. Currently, the establishment of new EN standards as well as amendments are being facilitated in various fields.

*EN: European Norm, which means European Standards. These standards are established by the European Committee for Standardization (CEN) and the European Committee for Electrotechnical Standardization (CENELEC).

*EC Machinery Directive "defines only the essential health and safety requirements of general application" and indicates the necessity for being "supplemented by a number of more specific requirements for certain categories of machinery." "...manufacturers to prove conformity to these essential requirements and (in order) to allow inspection for conformity to the essential requirements" (EC Directive 89/392)

For electrical equipment of machines, EN 60204-1 "Safety of machinery - Electrical equipment of machines" sets basics. The quickest way to acquire the CE marking is to satisfy the requirements of this EN Standard.

*EN 60204-1 is based on IEC 204-1, which is under the same title. As IEC 204-1 was largely amended in September 1992, the EN Standard was established in October 1992. EN 60204-1 has already been incorporated into the standards of various countries such as BS EN 60204-1 of UK and VDE 0113 of Germany.

*JIS B 6015 "Electrical equipment of machine tools" (1989) is said to have been established by transferring IEC 204-1 into a JIS standard; however, in reality, JIS B 6015 has incorporated Japan’s own electric power supply methods and cable standards, retaining a great deal of differences from the IEC standard. Furthermore, the IEC standard to which it refers is not the latest version which was amended in 1992 but the older version of 1981, which is also an issue.

<CE marking for cables>

CE marking allows manufacturers or importers to indicate their products’ essential conformity to applicable EC Directives by affixing the CE marking to their products or in some sort of relationship with the products. In other words, it is safe to say that this marking is an administrative symbol for free distribution throughout the EU market without receiving inspections of official institutions.

However, the CE marking is not a written warranty or a certificate of quality of a product.

To "warrant" conformity to standards and "certify quality," another mark certified by an official institution such as GS mark or VDE Certification Mark is required.

The CE marking is basically presented to the relevant authorities of EU Member States (therefore, it is not presented to end users.).

<Relationship with "Low Voltage Directive" and cables>

For the purpose of ensuring that cables are used in accordance with the intended applications of the cable’s main body, cable products designed to be used with the voltage between minimum AC 50 V AC and maximum 1000 V AC or between minimum 75 V DC and maximum 1500 V DC are subject to Low Voltage Directive when distributed in the EU market. This means that cables which do not fall under the voltage ranges mentioned above are not subject to this Directive. Typical cables not subject to the provisions of Low Voltage Directive include telephone lines and LAN data cables. In addition, cables eventually used outside the EU market are not subject to the Directive.

<Relationship with EMC Directive and Machinery Directive and cables>

EMC Directives specify matters about electromagnetic waves surrounding electrical and electronic equipment. The applicable equipment includes devices, facilities, and systems. A number of cables are fitted into equipment, facilities and systems. A cable wired inside or around equipment may have a decisive impact on the electromagnetic radiation of the equipment. However, European Standards for cables do not specify limit values in relation to electromagnetic waves or inspection methods for them.

Based on these current circumstances, it is impossible to prove a cable’s conformity to EMC Directive in relation to European Standards. Therefore, at this moment, conformity to EMC Directive cannot be proven by using the CE marking.

Machinery Directives specify that Low Voltage Directive shall be applied when a serious machine-related danger is expected to be caused by an electrical system. Many cables are used for the wiring of equipment, a large portion of which is included in the scope of application of Low Voltage Directive.

Neither Machinery Directive itself nor EN 60204-1 ("Safety of machinery - Electrical equipment of machines"), an European Standard which provides technical grounds to the Directive, directly requires the use of the cables conforming to the standards or the affixing of the CE marking to such cables. However, the EN Standard (EN 60204-1) clearly specifies selection criteria to which machinery manufacturers should pay attention when selecting cables suitable for the machinery from a technical perspective.

Differences from general JIS cables

Cables are directly related to electric power supply; therefore, it is particularly important to take into consideration safety standards of various countries. Most CE-compatible cables comply with VDE Standards, German domestic electric safety standards, and also satisfy the conditions of IEC standards (International Electrotechnical Commission) standards and CENELEC (European Committee for Electrotechnical Standardization) standards. For these reasons, CE-compatible cables can be used in almost entire Europe and in lots of countries (Some devices may require their cables to conform to the applicable standards of countries and to have the mark of the standards. e.g. Electrical appliances for consumer use).

While Japan is a member of IEC, IEC standards have a number of differences from JIS standards in terms of electrical safety. The following are major differences between JIS standard cables and IEC (European) standard cables:

- 1. Differences in the cross-sectional area of a conductor

- 2. Identification color of protective ground conductor

- 3. Identification color of the conductor of a multicore cable

- 4. Marking of rated voltage

- 5. Identification color of the single-core-wire conductor of appliance wiring

(1) Differences in the cross-sectional area of a conductor (Unit = mm2)

| IEC | 0.5---0.75---1.0---1.5---2.5---4.0---6.0---10---16---25---35 |

|---|---|

| JIS | 0.5---0.75---1.25---2.0---3.5---5.5---8---14---22------28--- |

As indicated above, the conductor sizes in JIS standards do not match the ones in IEC and European Standards. In particular, approximated JIS-specified sizes that correspond to IEC-specified sizes of 1.5 mm2 or larger do not match each other, which may cause inappropriate size selection.

(2) Identification color of protective ground conductor

European Standards specify the identification color of a protective conductor to be bi-colored stripes, spirals, etc. in 2 colors, green and yellow, with each color’s allocation rate of 70 percent or lower. Green is used in Japan and North America but not allowed in European regions (IEC 204-1 allows the use of green color in North America only). This provision is applied to protective conductors included in a multicore cable.

(3) Identification color of the conductor of a multicore cable

The identification colors of triple-core, quadruple-core cables, etc. used mainly as power cables in Japan are not typical in Europe.

| JIS | EN | |

|---|---|---|

| Triple-core | Black, White, Red | Brown, Blue, Green/Yellow (Black, Black, Green/Yellow) |

| Quadruple-core | Black, White, Red, Green | Brown, Black, Gray, Green/Yellow (Blue, Brown, Black, Green/Yellow) |

(4) Marking of rated voltage

IEC and European Standards specify to indicate rated voltages of control and power cables by using 2 voltage values in a form of Uo/U such as 300/500 and 450/750. (This applies to IEC Standards as well. e.g. IEC 227)

Uo = The voltage between a conductor and the ground

U = The voltage among conductors

This marking is in line with the power supply systems in Europe. Previously, the standard voltages of the indoor power supply were three-phase 380 V and single-phase 220 V in Continental Europe and three-phase 415 V and single-phase 240V in the UK. In the future, due to European integration, it has been decided that the standardized voltages of three-phase 400 V and single-phase 230 V will be used in entire Europe. The marking of the rated voltage of an European-Standard-compatible cable, Uo = 300 V, means that the cable supports single-phase 220 or 230 V and U = 500 means that it supports three-phase 380 or 400 V.

JIS standard-compatible cables with a rated voltage of 300 V or 600 V are not directly related to IEC or European Standards (testing standards and marking methods are different), having no grounds to be deemed as equivalent products.

(5) Identification color of a single-core wire in appliance wiring

IEC and European Standards specify the identification colors of a conductor for appliance wiring as follows: (IEC204-1、EN60204-1)

| Protective conductor: | Green/Yellow |

| Power circuit neutral conductor: | Light blue |

| AC or DC power supply circuit: | Black |

| AC control circuit: | Red |

| DC control circuit: | Blue |

| Interlock circuit whose power is supplied by an external power supply: | Orange |

IEC and European Standards prohibit the use of green or yellow if the cable may be confused with a protective conductor. JIS standards have also adopted the prohibition; however, in reality, yellow is often used for switchboard wiring in Japan, which requires attention.

Technical requirements for cables in EN 60204-1

The newly amended versions of IEC 204-1 and EN 60204-1 contain a number of amendments and additions to the former versions. As for cables, the following points are important in comparison with JIS standards:

- a. Test method for dielectric strength

- b. Allowable temperature for PVC insulator

- c. Calculation criteria of allowable current capacity

- d. Conductor’s minimum cross-sectional area at the part of use

a. Test method for dielectric strength

EN 60204-1 specifies that "for a cable that operates at a voltage higher than 50 V AC or 120 V DC, test voltage shall be minimum 2,000 V DC and duration shall be 5 minutes."

Withstand voltage test under JIS standards usually requires 1 minute.

b. Allowable temperature for PVC insulator

In Japan, tolerance for PVC cables is 60°C in general and heat-resistant PVC or any other insulator material is used for higher temperature. On the other hand, EN 60204-1 specifies allowable temperature for PVC as 70°C (maximum conductor temperature in normal conditions) as standard, which is used as assumption for the current calculation method. In Europe, most industrial cables meet the 70°C condition.

c. Calculation criteria of allowable current capacity

EN 60204-1 specifies the allowable current for each of installation methods listed below.

- Single-core wire + Conduit

- Multi-core cable + Conduit

- Installation on a wall (no conduit)

- Installation on an open cable tray

What requires attention is that in this case, too, the standard is the conductor’s cross-sectional area specified by European Standards. It is difficult to calculate actual allowable current based on the size specific to JIS standards.

d. Conductor’s minimum cross-sectional area

EN 60204-1 provides minimum usable sizes of the exterior and interior of an enclosure and types of cables. For example, the typical wiring of the exterior of an enclosure are as follows:

| Single core (stranded wire) | Single core (solid wire) | Multi core |

|---|---|---|

| 1mm2 | 1.5mm2 | 0.75mm2 |

*1 mm² and 1.5 mm² are the sizes not available in JIS cables, which requires attention.

EN 60204-1 also specifies different usages depending on the stranded wire structure of a conductor.

The strand structure classes are equivalent to those of IEC Standard (IEC 227) or VDE Standards.

Class 1: Solid wire for connecting fixed equipment

Class 2: Roughly stranded wire (IV-wire equivalent), normally 25 mm² or larger

Class 5: Finely stranded wire (KIV-wire equivalent), Mechanical operation of one migrating movement per hour

1. HAR Cables (Harmonised cables)

The representative standard currently integrated at the European level is HD21, a harmonized document established by CENELEC. This standard specifies matters such as test methods, standard specifications, product names, and marking methods for general single- and multi-core cables. In reality, cables conforming to the standard are used as power cords and other cables of household electrical appliances. (Note that the establishment of new EN standards for cables is underway.)

CENELEC standards-compliant cables are called "Harmonised Cables" and its conformity to the standards are indicated by the <HAR> mark.

As for single-core cables in Europe, Harmonised Cables such as H05V-K and H07V-K are generally used as machine cables.

As for multicore cables, CENELEC standard, HD21, currently specifies the sizes from 0.5 mm² to 4.0 mm² and the number of contacts of up to 5, not supporting various applications of machines. Therefore, in reality, other multicore cables than Harmonised Cables (VDE-standards-compatible products etc.) are selected for every purpose of applications such as for power supply, for control circuit, for robots, and so on.

[Example]

H07V-K 2.5

450/750 V rated

PVC insulation

Finely stranded wire for fixing

Single core, 2.5 mm2

| [Main codes for type and composition] | ||

|---|---|---|

| Item | Symbol | Meaning |

| Basic specification | H | European Unified Standards |

| Rated voltage | 05 07 |

300/500 450/750 |

| Insulator | V R |

PVC Natural rubber |

| Outer sheath | V R N |

PVC Natural rubber Chloroprene rubber |

| Conductor | U R K |

Solid wire Roughly stranded wire Finely stranded wire |

2. VDE Standards (Germany)

(VERBAND DEUTSCHR ELECTROTECHNISCHER e.V.)

VDE is the abbreviation for Verband Deutscher Elektrotechniker or the Association for Electrical, Electronic & Information Technologies. These standards developed by the organization are called VDE standards, mainly prescribing various matters about the safety of electrical products. VDE also conducts tests and provide certification in compliance with VDE standards to ensure the safety of electrical products. Their testing lab for this purpose is called VDE Testing and Certification Institute.