(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed that there will be no shipment from Japan during the upcoming year-end and New Year holiday period. However, Singapore’s stock items are available during these periods. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Design of chain drive mechanism 2

Selection method for low speed case

At a low chain speed of 50m/min or less, it is hardly necessary to consider stretching due to chain friction, and lifespan will be mainly determined by fatigue strength. In this case, selection of a low speed setting method is permitted rather than the “general case selection method”. The low-speed selection method is used for the case of a smooth transmission with few starts and stops, and the atmosphere, placement and lubrication etc all comply with the general case.

| Roller chain speed | Speed factor |

|---|---|

| 0~15 m/min | 1.0 |

| 15~30 | 1.2 |

| 30~50 | 1.4 |

| 50~70 | 1.6 |

-

(1) Grasp of usage conditions

Same as [General case selection method]. -

(2) Selection of chain and no. of small sprocket teeth

From Table 3 Simple Selection Table choose a slightly smaller chain and sprocket from the rotational speed (r/min) and motor (kW). -

(3) Calculation of chain speed

- V

- : Chain speed (m/min)

- P

- : Chain pitch (mm)

- N

- : No. of sprocket teeth

- n

- : Sprocket rotational speed (r/min)

-

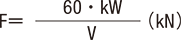

(4) Calculation of chain maximum acting load

Finds the maximum load acting on the chain.

- F

- : Load on the chain (kN)

- V

- : Chain speed (m/min)

- kW

- : Power transmission (kW)

-

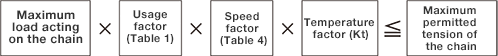

(5) Decision on used factors

The used factors are found from the Used factors table (Table 1). -

(6) Decision on speed factors

Finds the speed factor from the chain speed calculated in (3). -

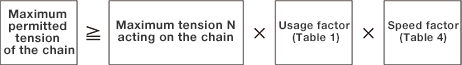

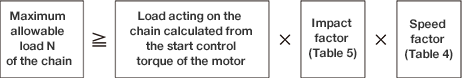

(7) Study of maximum allowable tension of the chain

Substitute the values found in (4) - (6) in the selected formula, compare the result with the maximum allowable tension of the chain selected in (2) and consider if it satisfies the selection formula.

If not satisfied, change the chain and sprocket and consider again. -

(8) Check of the no. of teeth and shaft diameter of the large sprocket,

and calculate the chain length

The selection below is the same as “General case selection method”.

Selection method when impact load acts at low speed

Under conditions where there are many sudden start/stops, or reverse braking or braking, and the

action of many impact loads, the inertia (GD2) of the motor or non-motor must be taken into

account.

Compared with the general transmission case, sufficient care is required because a rather large

load is acting on the chain.

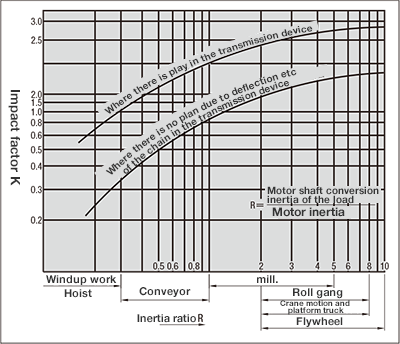

Impact factor

The constants determined by the inertia ratio (GD2 ratio) of the motor and the driven machinery

and the size of the motor play are shown in (Table 5). Note that where the play is extremely

large, an impact larger than that value may be acting.

Selection method of the stainless steel roller chain (CHES)

Please used the low speed selection method as the stainless steel roller chain selection method.

- 1) Maximum allowable tension is lower for CHES (stainless steel type) compared to the CHE (steel type) roller chain.

- 2) Please avoid use of the offset link as far as possible.

Temperature selection method

Roller chain temperature selection method

This is the size selection method anticipating reduction in strength due to temperature.

-

1)

Problems with roller chain transmission at high temperatures

(1) Increased friction due to decline in hardness

(2) Increased stretch due to hardening

(3) Oiling defects and flex defects due to oil deterioration and carbonization, increased friction

(4) Increased friction and flex defects due to occurrence of scale -

2)

Problems with roller chain transmission at low temperatures

(1) Decline in impact strength due to low temperature brittleness

(2) Coagulation in the lubricant oil

(3) Faulty flex due to snow or ice attached

| Temperature | CHE Roller chain | |

|---|---|---|

| Less than CHE60 | Greater than CHE80 | |

| Less than −60℃ | − | − |

| Greater than -60℃ to -50℃ | − | − |

| Greater than -50℃ to -40℃ | − | Not used |

| Greater than -40℃ to -30℃ | Not used | Catalog value × 1/4 |

| Greater than -30℃ to -20℃ | Catalog value × 1/4 | Catalog value × 1/3 |

| Greater than -20℃ to -10℃ | Catalog value × 1/3 | Catalog value × 1/2 |

| Greater than -10℃ to 60℃ | Catalog value | Catalog value |

| Greater than 60℃ to 150℃ | Catalog value | Catalog value |

| Greater than 150℃ to 200℃ | Catalog value × 3/4 | Catalog value × 3/4 |

| Greater than 200℃ to 250℃ | Catalog value × 1/2 | Catalog value × 1/2 |

| Above 250℃ | Not used | Not used |

Selection method at high temperature of stainless steel roller chain

(1) Up to 400℃ use the low speed selection method. (General selection method cannot be

used.)

(2) Above 400℃ use the temperature factor shown in the table below.

(3) Selection method

| Temperature | Factor (Kt) |

|---|---|

| Less than 400℃ | 1.0 |

| Greater than 400℃ to 500℃ | 1.2 |

| Greater than 500℃ to 600℃ | 1.5 |

| Greater than 600℃ to 700℃ | 1.8 |

| Above 700℃ | Not used |

Corrosion resistance decreases above 400℃, so please take that into consideration in selection.

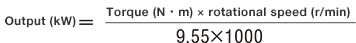

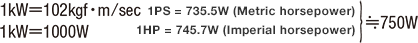

Conversion of output and torque

- Torque:

- 1kg・m=100kg・cm

- 1kg・m=9.8N・m (Newton torque)

- 1N・m=0.120kg・m

- 1r/min =1rpm

When displayed as a combination of torque and rotational speed