(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed that there will be no shipment from Japan during the upcoming year-end and New Year holiday period. However, Singapore’s stock items are available during these periods. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

How to Select Ball Screws: Page 2

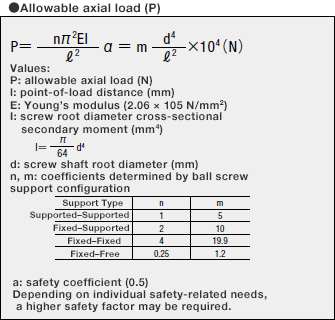

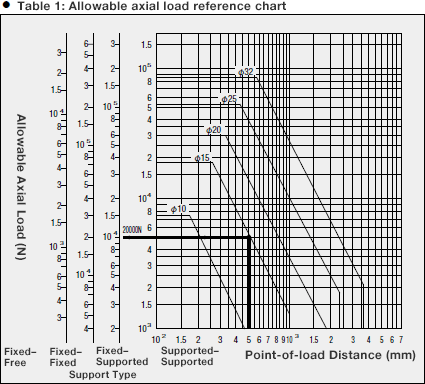

4. Allowable Axial Load

Allowable axial load is a load that ensures safety, calculated taking into account the buckling

load, which is a load that may cause the screw thread section to buckle.

The maximum axial load applied to the screw thread must be equal to or less than the allowable

axial load.

Allowable axial load can be calculated using the formula below.

Alternatively, Table 1 may be used to easily check the allowable axial load based on screw

thread diameter by reading the value indicated by the allowable axial load line.

Example of Calculating Allowable Axial Load

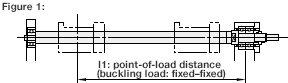

Calculate the allowable axial load based on the conditions in Figure 1.

Usage conditions:

- Screw thread diameter is φ15, lead is 5

- Mounting configuration is fixed–fixed

- Point-of-load distance (ℓ1) is 820 mm

- Screw root diameter (d) is 12.5

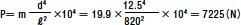

Calculation:

Because a fixed–fixed mounting configuration is used, m is 19.9, and allowable axial

load P is calculated as follows:

Therefore, the maximum axial load is 7,225 N.

Example of calculating Screw Thread Diameter to Meet Usage Conditions

Usage conditions:

- Point-of-load distance is 500 mm

- Mounting configuration is fixed–fixed

- Maximum axial load is 20,000 N

Selection:

(1) Using Table 1, confirm the point of intersection when using the vertical line

for a 500-mm point-of-load distance and the horizontal line for an allowable axial

load of 20,000 N with a “fixed–supported” support configuration.

(2) The point at which these lines intersect indicates that an allowable thread

diameter of 15 mm or more should be selected.

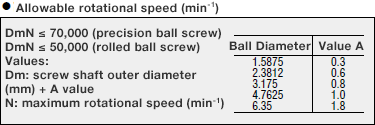

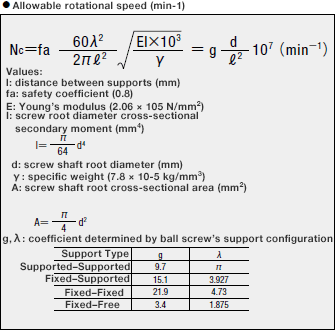

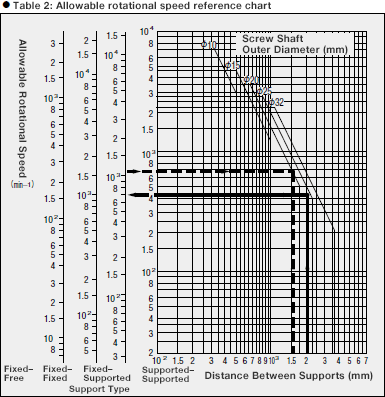

5. Allowable Rotational Speed

The ball screw’s rotational speed is determined based on the required feed rate and ball screw

lead, and must be equal to or less than the allowable rotational speed.

The allowable rotational speed is determined based on two considerations: the critical speed of

the rotary shaft and the rotational speed limit (DmN value) for the ball that rotates within the

nut.

5-1. Critical Speed

The ball screw’s allowable rotational speed is 80% of the critical speed at which the ball

screw’s rotational speed resonates with the natural frequency of the screw shaft.

Allowable rotational speed can be calculated using the formula below.

Alternatively, Table 2 may be used to easily confirm the allowable rotational speed based on

screw thread diameter by reading the value indicated by the allowable rotational speed line.

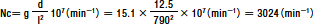

Example of Calculating Allowable Rotational Speed

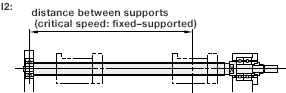

Calculate the allowable rotational speed based on the conditions in Figure 2.

Usage conditions:

- Screw thread diameter is φ15, lead is 5

- Mounting configuration is fixed–supported

- Point-of-load distance (l2) is 790 mm

Calculation:

Because a fixed–supported mounting configuration is used, g is 15.1, and

allowable

rotational speed Nc is calculated as follows:

Therefore, the maximum rotational speed is 3,024 min-1.

Example of Calculating Allowable Rotational Speed

Usage conditions:

- Screw shaft outer diameter is 20

- Distance between supports is 1,500 mm

- Mounting configuration is fixed–supported

Calculation:

(1) Using Table 1, check the point of intersection when using the vertical line for

a distance between supports of 1,500 mm and the horizontal line for a screw shaft

outer diameter of φ20.

(2) The point at which these lines intersect for a fixed–supported configuration

indicates an allowable rotational speed of 1,076 min-1.

Example of calculating Screw Thread Diameter to Meet Usage Conditions

Usage conditions:

- Distance between supports is 2,000 mm

- Maximum rotational speed is 1,000 min-1

- Mounting configuration is fixed–fixed

Calculation:

(1) Using Table 2, confirm the point of intersection when using the vertical line

for a distance between supports of 2,000 mm and the horizontal line for an allowable

rotational speed of 1,000 min-1 with a “fixed–fixed” support

configuration.

(2) The point at which these lines intersect indicates a shaft diameter tolerance

value of 25 mm, which fulfills the diameter requirement for a maximum rotational

speed of 1,000 min-1.

5-2. DmN Value

The higher the orbital speed of the steel balls within the nut, the greater the impacting force

applied to the rotating section, resulting in damage to it.

The relevant threshold value is known as the DmN value.

It can be calculated as follows.