(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed that there will be no shipment from Japan during the upcoming year-end and New Year holiday period. However, Singapore’s stock items are available during these periods. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Appropriate Tightening Axial Force of Bolts / Appropriate Tightening Torque

- Tightening axial force and fatigue limit when fastening with bolts

- Calculation of tightening axial force and tightening torque

- Calculation examples

- Initial tightening force and tightening torque

Tightening axial force and fatigue limit when fastening with bolts*1

- Calculation of the appropriate tightening axial force when tightening bolts shall be within the elastic range of 70% of the standard yield resistance at the maximum with the torque method.

- Fatigue strength of bolts due to repeated loading shall not exceed the allowable value.

- The bolt and nut bearing surfaces are not allowed to cave in due to the fastened object.

- Tightening does not damage the fastened object.

Calculation of tightening axial force and tightening torque

The relation of the tightening axial force Ff is shown by equation (1).

Ff=0.7×σy×As……(1)

Tightening torque Tfa can be obtained from equation (2).

TfA=0.35k(1+1/Q)σy・As・d……(2)

- k

- : Torque coefficient

- d

- : Bolt nominal diameter [cm]

- Q

- : Tightening coefficient

- σy

- : Yield resistance (1098 N/mm2 {112 kgf/mm2} when strength class is 12.9)

- As

- : Bolt effective cross-sectional area [mm2]

Calculation examples

Find the appropriate torque and axial force when tightening mild steel to mild steel with M6 hex socket head cap screw (strength class 12.9) *2 with oil lubrication.

-

Appropriate torque is calculated from equation (2)

TfA=0.35k(1+1/Q)σy・As・d

=0.35・0.175(1+1/1.4))1098・20.1・0.6

=1390[N・cm]{142[kgf・cm]} -

Axial force Ff is calculated from equation (1)

Ff=0.7×σy×As

=0.7×1098×20.1

=15449{[N]1576[kgf]}

| Bolt surface treatment lubrication | Torque coefficient k |

Combination Material of the fastened object (a) - female thread material (b) |

|

|---|---|---|---|

| Steel bolt black oxide coating oil lubrication | 0.145 | SCM−FC FC−FC SUS−FC | |

| 0.155 | S10C−FC SCM−S10C SCM−SCM FC−S10C FC−SCM | ||

| 0.165 | SCM−SUS FC−SUS AL−FC SUS−S10C SUS−SCM SUS−SUS | ||

| 0.175 | S10C−S10C S10C−SCM S10C−SUS AL−S10C AL−SCM | ||

| 0.185 | SCM−AL FC−AL AL−SUS | ||

| 0.195 | S10C−AL SUS−AL | ||

| 0.215 | AL−AL | ||

| Steel bolt black oxide coating non- lubrication | 0.25 | S10C−FC SCM−FC FC−FC | |

| 0.35 | S10C−SCM SCM−SCM FC−S10C FC−SCM AL−FC | ||

| 0.45 | S10C−S10C SCM−S10C AL−S10C AL−SCM | ||

| 0.55 | SCM−AL FC−AL AL−AL | ||

- S10C

- : Non heat-treated mild steel

- SCM

- : Heat-treated steel (35JRC)

- FC

- : Cast iron (FC200)

- AL

- : Aluminum

- SUS

- : Stainless steel (SUS304)

| Tightening coefficient Q |

Tightening method | Surface condition | Lubrication condition | |

|---|---|---|---|---|

| Bolt | Nut | |||

| 1.25 | Torque wrench | Manganese phosphate | Not treated or phosphate | Oil lubrication or MoS2 paste |

| 1.4 | Torque wrench | Not treated or phosphate | ||

| Wrench with torque limit | ||||

| 1.6 | Impact wrench | |||

| 1.8 | Torque wrench | Not treated or phosphate | Not treated | No lubrication |

| Wrench with torque limit | ||||

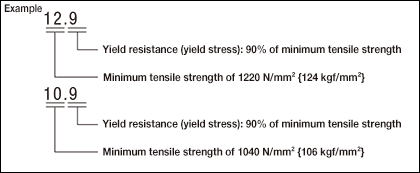

Strength class expression

Initial tightening force and tightening torque*2

| Nominal thread size | Effective cross-sectional area As mm2 |

Strength class | |||||

|---|---|---|---|---|---|---|---|

| 12.9 | 10.9 | ||||||

| Yield load | Initial tightening force | Tightening torque | Yield load | Initial tightening force | Tightening torque | ||

| N{kgf} | N{kgf} | N・cm {kgf・cm} |

N{kgf} | N{kgf} | N・cm {kgf・cm} |

||

| M3×0.5 | 5.03 | 5517{563} | 3861{394} | 167{17} | 4724{482} | 3312{338} | 147{15} |

| M4×0.7 | 8.78 | 9633{983} | 6742{688} | 392{40} | 8252{842} | 5772{589} | 333{34} |

| M5×0.8 | 14.2 | 15582{1590} | 10907{1113} | 794{81} | 13348{1362} | 9339{953} | 676{69} |

| M6×1 | 20.1 | 22060{2251} | 15445{1576} | 1352{138} | 18894{1928} | 13220{1349} | 1156{118} |

| M8×1.25 | 36.6 | 40170{4099} | 28116{2869} | 3273{334} | 34398{3510} | 24079{2457} | 2803{286} |

| M10×1.5 | 58 | 63661{6496} | 44561{4547} | 6497{663} | 54508{5562} | 38161{3894} | 5557{567} |

| M12×1.75 | 84.3 | 92532{9442} | 64768{6609} | 11368{1160} | 79223{8084} | 55458{5659} | 9702{990} |

| M14×2 | 115 | 126224{12880} | 88357{9016} | 18032{1840} | 108084{11029} | 75656{7720} | 15484{1580} |

| M16×2 | 157 | 172323{17584} | 120628{12309} | 28126{2870} | 147549{15056} | 103282{10539} | 24108{2460} |

| M18×2.5 | 192 | 210739{21504} | 147519{15053} | 38710{3950} | 180447{18413} | 126312{12889} | 33124{3380} |

| M20×2.5 | 245 | 268912{27440} | 188238{19208} | 54880{5600} | 230261{23496} | 161181{16447} | 46942{4790} |

| M22×2.5 | 303 | 332573{33936} | 232799{23755} | 74676{7620} | 284768{29058} | 199332{20340} | 63896{6520} |

| M24×3 | 353 | 387453{39536} | 271215{27675} | 94864{9680} | 331759{33853} | 232231{23697} | 81242{8290} |

| Nominal thread size | Effective cross-sectional area As mm2 |

Strength class | ||

|---|---|---|---|---|

| 8.8 | ||||

| Yield load | Initial tightening force | Tightening torque | ||

| N{kgf} | N{kgf} | N・cm {kgf・cm} |

||

| M3×0.5 | 5.03 | 3214{328} | 2254{230} | 98{10} |

| M4×0.7 | 8.78 | 5615{573} | 3930{401} | 225{23} |

| M5×0.8 | 14.2 | 9085{927} | 6360{649} | 461{47} |

| M6×1 | 20.1 | 12867{1313} | 9006{919} | 784{80} |

| M8×1.25 | 36.6 | 23422{2390} | 16395{1673} | 1911{195} |

| M10×1.5 | 58 | 37113{3787} | 25980{2651} | 3783{386} |

| M12×1.75 | 84.3 | 53949{5505} | 37759{3853} | 6605{674} |

| M14×2 | 115 | 73598{7510} | 51519{5257} | 10486{1070} |

| M16×2 | 157 | 100470{10252} | 70325{7176} | 16366{1670} |

| M18×2.5 | 192 | 126636{12922} | 88641{9045} | 23226{2370} |

| M20×2.5 | 245 | 161592{16489} | 113112{11542} | 32928{3360} |

| M22×2.5 | 303 | 199842{20392} | 139885{14274} | 44884{4580} |

| M24×3 | 353 | 232819{23757} | 162974{16630} | 57036{5820} |

Notes

- *1 Bolt tightening methods include torque method, torque gradient method, rotation angle method, elongation measurement method, etc., but the torque method is widely used because it is simple.

-

*2 Tightening conditions: Use torque wrench (surface

oil lubrication, torque

coefficient k = 0.17, tightening coefficient Q = 1.4)

As torque coefficient changes depending on usage conditions, use this table as a

reference.

This table is an edited excerpt from the Kyokuto MFG. Co., Ltd. catalog.