(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

What is tolerance/design? (Tolerance design 1)

Are you not designing using only IEB (intuition, experience, and boldness)?

Here we provide an easy-to-understand explanation of the advantages of tolerance design, and the requisite knowledge.

- What is tolerance/design?

- Tolerance design advantages / calculation examples

Tolerance design technology supported the strength of Japanese manufacturing, and is now attracting attention once again.

We will give an overview of exactly what "tolerance" is, and its importance.

What is "tolerance"?

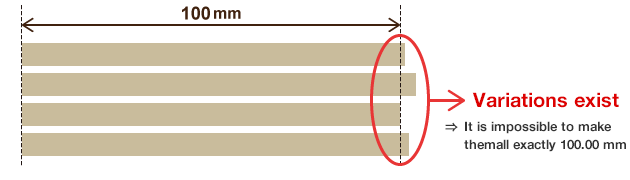

Let us assume that we wish to machine a cylindrical metal rod with a length of 100mm.

Even if we intend to machine them all in the same way, because there are variations in dimensions and shape, it is not possible to finish all the metal rods to exactly 100.00mm.

Design and manufacturing sites work to reduce such variations, but despite this it is not possible to remove them entirely.

Even when intending to machine them all the same way, variations in dimensions and shape occur

Such variations in dimensions and shape are basically centered on the target value, occurring above and below it.

Furthermore, depending on the application for this metal rod, allowable upper and lower limits will be set for variations relative to the target dimensions.

The difference between these two values (the permissible range) is referred to as "tolerance."

Tolerance is indispensable in manufacturing in these ways. How do you set tolerance?

Perhaps you use the tolerance that was set for drawings of previous similar parts, or take IEB (intuition, experience, and boldness) approach without careful consideration to determine tolerance?

The tolerance values set have a significant impact on product cost, performance, and quality.

For that reason, it is no exaggeration to say that designing that exerts proper control over tolerances and efforts to improve technology related to tolerance design lead in turn to enhancements in manufacturing competitiveness.

What is "tolerance design"?

Generally speaking, concepts related to "tolerance" can be summarized as follows.

"Individual parts inevitably have variations in their dimensions, and ultimately parts should be finished so that they are within the range of tolerances specified in the drawing."

This is how the approach to tolerance is seen on the machining side.

In manufacturing, the designer must determine the permissible range for this variation (tolerances), after comprehensive consideration of factors such as product specification and the cost of parts.

Depending on the tolerances thus set, an overall judgment must be made, based on whether the ultimate specification of the product will be satisfactory or whether machining to these tolerances is actually possible.

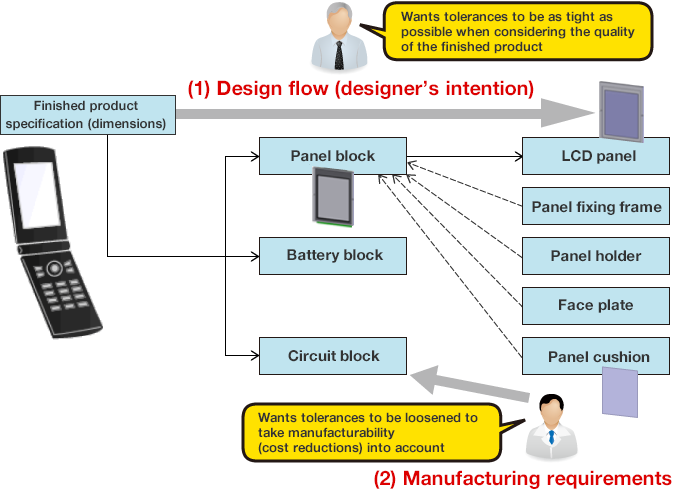

In actual design, tolerances are set as shown in the figure below.

How tolerances are determined

In order for the finished product specification to be within a certain range, it is necessary for each unit to also be within a certain range, with tolerances being allocated to each of them.

This is the original "(1) Design flow," which reflects the intention of the designer.

While from those focused on the finished product there are requests for tolerances be as tight as possible to make it compact and low profile, conversely, from those focused on the parts used there are requests for tolerances to be loosened to improve manufacturability (cost reductions). This is "(2) Manufacturing requirements."

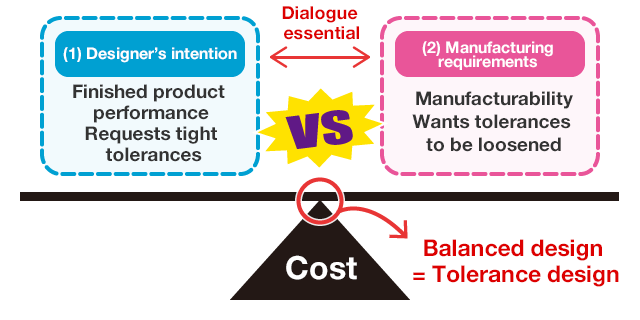

Naturally, if the tolerances for individual parts are made tighter (smaller), costs will rise accordingly, and if tolerances are loosened (made larger) this will lead to a higher risk of defects in the finished product and, in some cases, to an increase in total costs.

Tolerances are set by projecting the "Designer's intention (1)" and "Manufacturing requirements (2)" onto the shared axis of economics (cost), and finding the balancing point.

In such situations, including statistical considerations in calculations to set tolerances is called "tolerance design."

In recent years a variety of factors, such as the relocation of manufacturing overseas, have made it more difficult in many cases for "(2) Manufacturing requirements" to be conveyed to designers, and so for tolerance design it is essential that a system is established to enable smooth dialogue between (1) and (2).