(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed that there will be no shipment from Japan during the upcoming year-end and New Year holiday period. However, Singapore’s stock items are available during these periods. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Cable Basics

- Allowable current calculation formula

- Voltage drop

- Cable classification

- Classification by location of use

- Classification by application

- Classification of rated temperature and rated voltage

- Selecting a cable

- What is sheath resistance?

- Noise

- Considering noise resistance

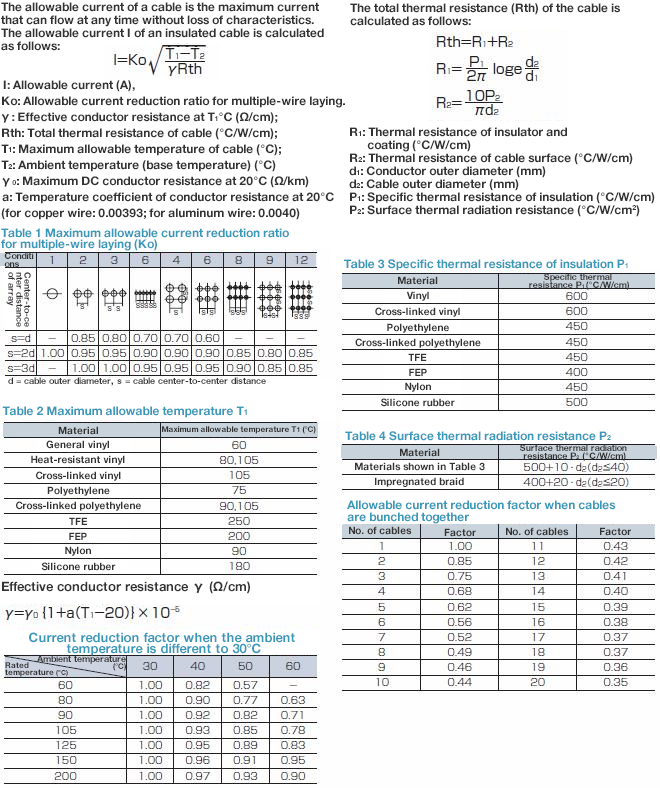

Allowable current calculation formula

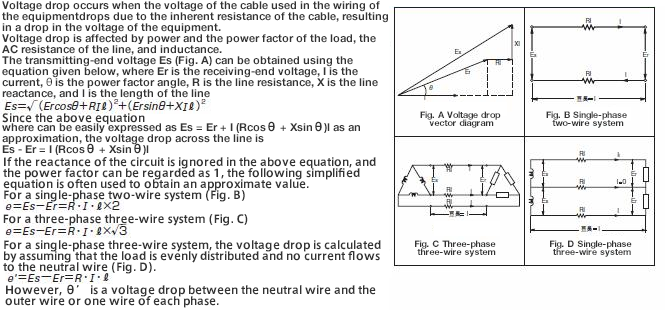

Voltage drop

Cable classification

As a guideline for selecting proper cables, the manufacturer’s “Wiring Components Catalog” classifies various types of cables from different perspectives.

-

1.

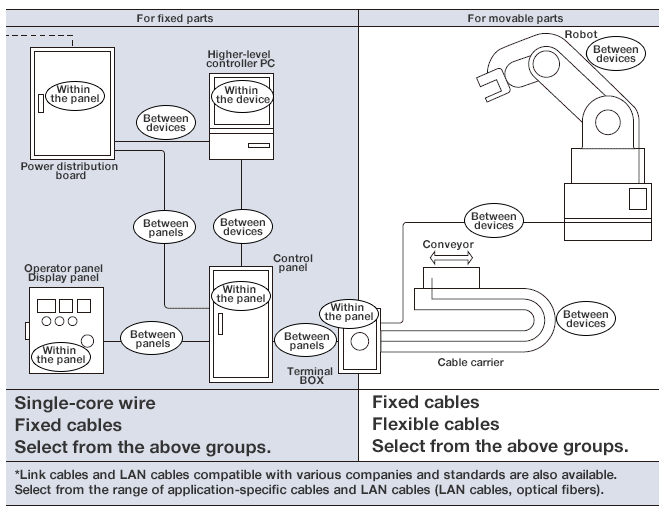

Classification by location of use

Wires and cables are further classified and listed based on their purpose and location of use into the following categories — “For connections within a panel” and “For connection between panels/devices.” -

2.

Classification by application

This section clarifies the structures and functions of various cables. Use this as a selection guideline when classifying and using cables as power supply lines and electrical transmission lines for electrical or electronic equipment. -

3.

Classification of rated temperature and rated voltage

Rated voltages of both single-core cables and multi-core cables are listed in the order of 600 V, 300 V, and less than 100 V. Each cable’s heat-resistant operating temperature range is mentioned in an easy-to-read location in the catalog. -

4.

Standard-based classification

Each country has its own standards for the use of electrical components. Select a cable that meets the standards or is compatible with the standards stipulated in your country.

Classification by location of use

The classification of cables into the categories “For connections within a panel” and “For connections between panels/devices,” based on the purpose and location of use, serves as a guideline for selecting cables.

Classification by application

Based on their application, cables for electrical/electronic equipment are classified into two

main categories—power supply cables and electrical signal transmission cables. In the case of

power supply cables, the level of voltage and current of the electricity passing through the

cable is an important factor, whereas in the case of electrical signal transmission cables, the

method by which electric signals are transmitted is important.

Understanding the structure and function of cables can serve as a guideline for selecting

appropriate cables.

-

1.

Power supply cables

As power supply cables serve as a point of contact with electric power, they are directly related to the safety regulations of each country, including the Interior Wring Regulations (Note 1). These safety rules and regulations must be considered when selecting the required power supply cables. The Interior Wiring Regulations (Note 1) were established in November 1968 by the Electrotechnical Standards Investigation Committee of the Japan Electric Association as a nationwide standard for the design, installation, and management of electrical facilities at demand points, and are available in the form of booklets.

The Japan Electric Association TEL (03) 3216-0555 (switchboard number) -

2.

Electrical signal transmission cables

Electronic equipment such as computers and data communication equipment require cables with various electrical characteristics. Cables between the peripheral devices of a computer are a part of a heavy transmission circuit. The following factors need to be considered when selecting the required cables:- 1. The cables should have the electrical characteristics needed for transmitting signals between the devices

- 2. Noise prevention (shielding, twisted pairs, etc.)

- 3. The cables must have a certain degree of flexibility (wiring in confined places should be possible)

Classification of rated temperature and rated voltage

“Rated temperature” refers to the lowest temperature at which the cable does not embrittle and

the highest temperature at which the cable does not soften or deteriorate due to heating. Rated

temperature may differ depending on the insulation material. Refer to the operating temperature

range mentioned on each product page of the catalog, and make a decision accordingly. However,

please note that in practice, it is not possible to use the product at its maximum operating

temperature.

“Rated voltage” refers to the highest voltage that may be continuously applied to the cable

without causing dielectric breakdown. Generally, cables rated at 600 V, 300 V and less than 100

V are used “For connections within a panel” and “For connections between panels/devices.” Please

refer to every title on every product page to make a judgment based on the voltage indication of

the product.

Selecting a cable

Various factors such as the applicable voltage, minimum and maximum current, direct current and

alternate current need to be considered when selecting cables for electrical/electronic

equipment.

However, unlike power cables and communication cables, there are several types of cables for

electrical/electronic equipment with hardly any standardization, making the selection process

difficult. Therefore, to ensure you select the right cables, define the required electrical

characteristics, required mechanical characteristics such as flex-resistance, flexibility, oil

resistance, and the required operating environment. Then, choose cables that meet those

requirements. Additionally, when the cables are to be connected to connectors and terminals

(when making a cable harness), physical requirements such as compatible cable size and

compatible finishing of the outer diameter should also be considered.

Selecting the size

Consider the following factors when selecting cable size:

- 1. The cable’s allowable current and load current

- 2. Voltage drop

In addition, consider the load on the cable and the overall demand. For example, if the cable is

short in length, the size of the cable may be selected based on the allowable current because

the degree of voltage drop is less in shorter cables. On the other hand, the voltage drop is

higher if the cable is long, hence you need to choose a large-diameter cable.

*Click here for more information on voltage drop.

What is sheath resistance?

The sheath is the cable’s outer coating.

The basic purpose of the sheath is to protect the conductor and insulator inside the cable from

getting wet or damaged.

Although certain sheaths protect cables from specific loads such as repetitive actions of

bending or sliding, or exposure to ultraviolet rays and oil, no sheaths provide protection from

all types of external loads. Therefore, a suitable sheath material should be selected according

to the purpose and conditions of use.

For example, “PVC (polyvinyl chloride),” is often chosen because it is relatively inexpensive.

However, although PVC has improved oil and heat resistance to withstand harsh environments, and

enhanced softness and smoothness to achieve flexibility, PVC may produce toxic gases and dioxins

when burned. Hence, PE (polyethylene) may be used instead for environmental reasons.

FEP (fluoropolymer), which has high heat resistance, weather resistance and mechanical strength,

is also used for robot cables even though it is costlier.

Noise

Noise usually refers to any voltage, current or signal other than that intended. Noise can cause

equipment to malfunction.

Noise such as induced noise, radiated noise and conducted noise is associated with robot

cables.

For example, noise travelling through a robot cable may escape the equipment in the form of

“radiated noise,” or radiated noise may come in contact with robot cables and be emitted in the

form of “conducted noise.”

Noise is a complex interplay of causes and routes that not only affects robot cables,

but also

the peripheral equipment.

Although it may not be possible to solve every issue by only addressing noise prevention in

robot cables, eliminating the cause of noise in one component at a time is an important step.

Considering noise resistance

Noise prevention in robot cables is achieved by shielding.

Robot cables that are shielded for noise prevention are labeled as “Shielded” or

“Noise-resistant” in the product name and specification.

Braided shielding is a type of shield wherein tin-plated annealed copper wire is braided between

the insulator and the sheath.

In braiding, copper wires and fibers are tightly woven in a mesh-like pattern and used to

encapsulate the cable.

Information in the sections “What is sheath resistance?”, “Noise,” and “Considering noise resistance” is based on technical data from Taiyo Cabletec Corporation.