(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

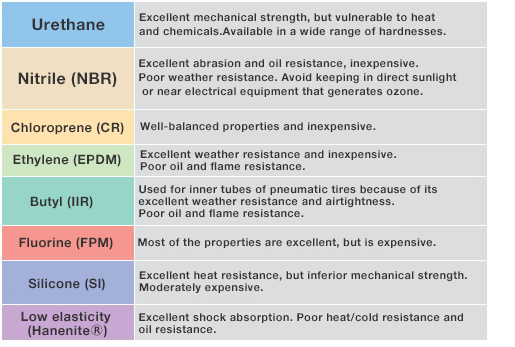

Properties and Features of Various Rubbers

Features

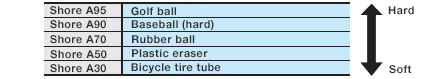

Approximate Shore hardnesses of urethane and rubber

Approximate hardness

- Permissible range of hardness: ±5 of the stated value.

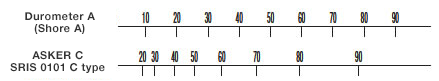

Gel hardness

Gel hardness is expressed in terms of Asker C and needle penetration.

An approximate correlation between Asker C and Shore A, which is a measure of the hardness of

urethane and rubber, is shown below.

*The needle penetration measurement is standardized in JIS K2207. A needle of a regulated weight is inserted vertically into a sample, and the hardness of the sample is determined from the length of the needle’s penetration.

A needle penetration value of 1/10 mm indicates needle penetration 1. (The higher the number, the softer the material.) It is, therefore, difficult to make relative comparisons with Shore or Asker, and hence a comparison chart has not been provided.

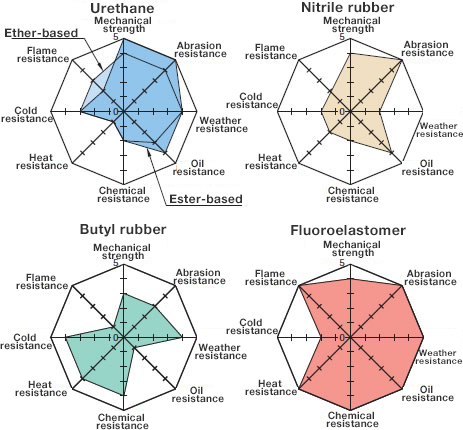

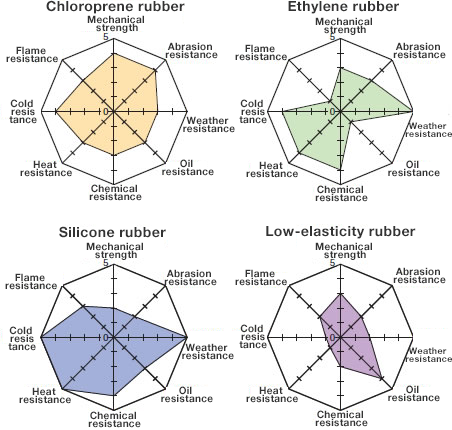

Property Comparison Graph

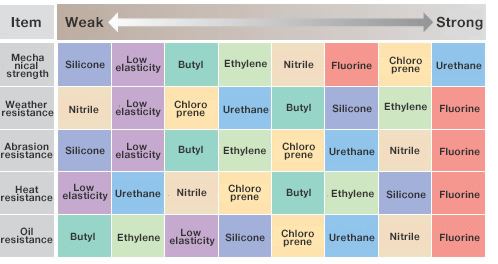

Property Order

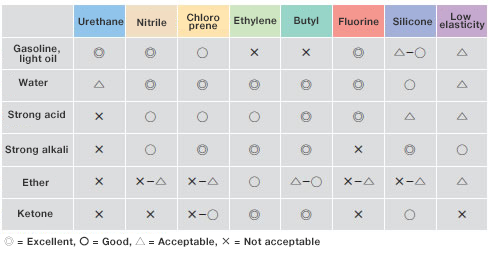

Comparison of Chemical Resistance

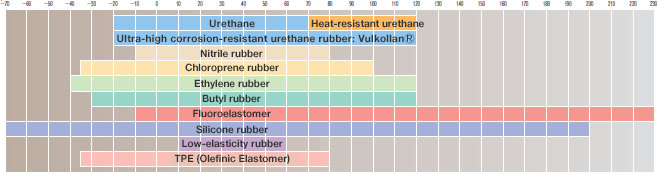

Comparison of heat resistance: Vulkollan® can be used for a prolonged period at 80°C, and for a short period of 15 to 20 minutes at 120°C. Heat-resistance temperature (°C)

Values of Properties

| Item | Unit | Urethane | Low-resilience urethane | Ultra-low hardness urethane | ||||

|---|---|---|---|---|---|---|---|---|

| Specific gravity | − | 1.13 | 1.13 | 1.20 | 1.15 | 1.20 | 1.03 | 1.02 |

| Hardness | Shore A | 95 | 90 | 70 | 50 | 30 | 70 | 15 |

| Tensile strength | MPa | 44.1 | 44.6 | 31.3 | 27.4 | 18.5 | 11.8 | 0.6 |

| Strain | % | 400 | 530 | 650 | 690 | 600 | 250 | 445 |

| Heat resistance | ℃ | 70 | 70 | 70 | 70 | 70 | 70 | 80 |

| Cold resistance | ℃ | −40 | −20 | −20 | −20 | −20 | −20 | −40 |

Each tensile strength and strain value has been tested in accordance with JIS standard K6251.

Comparison of Properties of Urethane (Ether-based and Ester-based)

| Characteristics | Ether-based (Shore A95/90) | Ester-based (Shore A70/50/30) | |

|---|---|---|---|

| Tensile strength | ○ | ||

| Strain | ○ | ||

| Tear strength | ○ | ||

| Rebound resilience | ○ | ||

| Abrasion resistance | Sliding wear | ○ | |

| Impingement wear | ○ | ||

| Hydrolysis resistance | ○ | ||

| Oil resistance | ○ | ||

| Strength | ○ | ||

| Durability | ○ | ||

| Acid resistance, alkali resistance | ○ | ||

Values of Properties

Each tensile strength and strain value has been tested in accordance with JIS standard K6251.

| Item | Unit | Nitrile rubber | Chloroprene rubber | Ethylene rubber | Butyl rubber | Fluoroelastomer | Silicone rubber | High-strength silicone rubber | Low-elasticity rubber | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specific gravity | − | 1.6 | 1.3 | 1.6 | 1.2 | 1.5 | 1.8 | 1.9 | 1.2 | 1.2 | 1.2 | 1.3 | 1.2 | |||

| Hardness | Shore A | 70 | 50 | 65 | 65 | 65 | 80 | 60 | 70 | 50 | 50 | 57 | 32 | |||

| Tensile strength | MPa | 12.7 | 4.4 | 13.3 | 12.8 | 7.5 | 12.5 | 10.8 | 7.4 | 8.8 | 7.8 | 8.3 | 10.3 | |||

| Strain | % | 370 | 400 | 460 | 490 | 380 | 330 | 270 | 300 | 330 | 400 | 810 | 840 | |||

| Maximum operating temperature | ℃ | 90 | 99 | 100 | 120 | 120 | 230 | 230 | 200 | 200 | 200 | 60 | 60 | |||

| Continuous operating temperature | ℃ | 80 | 80 | 80 | 80 | 80 | 210 | 210 | 150 | 150 | 150 | 30 | 30 | |||

| Cold resistance | ℃ | −10 | −10 | −35 | −40 | −30 | −10 | −10 | −70 | −70 | −50 | 10 | 10 | |||

Adhesion of Urethane, Rubber, Sponge

For products with seals, double-sided adhesive seals that are suitable for the material are used.

Double-sided adhesive seals and adhesives for urethane, rubber and sponge are also sold separately on the manufacturer’s website.

| Model | W | Compatible rubber material | Base material | Main constituent | |||

|---|---|---|---|---|---|---|---|

| Standard type | Heat-resistant type | Conductive type | Oil-resistant type | ||||

| ADTR | − | LADTR | PLADTR | 20 | Nitrile, chloroprene, ethylene, butyl, fluorine | Non-woven polyester | Acrylic pressure-sensitive adhesive |

| 50 | |||||||

| ADTS | HADTS | − | − | 20 | Silicone |

Standard: Polyester film Heat-resistant: Polyimide film |

Silicone pressure-sensitive adhesive |

| 50 | |||||||

LADTR rolls are 5 m in length; the rest are 10 m.

Only the white release-paper side (silicone adhesive side) of ADTS adheres to silicone rubber.

Adhesive Strength Test Data

180° peel test: A rubber sheet 1 mm thick, 25 mm wide is glued to a SUS304 plate. The load required to peel the two components apart is expressed in terms of adhesive strength (N).

| Conditions | Standard type | Heat-resistant type | Conductive type | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ADTR | ADTS | HADTS | LADTR | ||||||||

| Nitrile | Chloroprene | Ethylene | Butyl | Fluorine | Silicone | Silicone | Nitrile | Chloroprene | Ethylene | Butyl | |

| Room temperature × 20 minutes | 60 | 60 | 60 | 60 | 60 | 13 | 3 | 6 | 6 | 6 | 6 |

| Room temperature × 72 hours | 80 | 80 | 80 | 80 | 80 | 15 | 9 | 9 | 9 | 9 | 9 |

| 80°C × 48 hours | 70 | 70 | 70 | 70 | 70 | 15 | 10 | 13 | 14 | 12 | 12 |

The above adhesive strengths are examples of measured values, and are not guaranteed values.

| Item | Oil-resistant type | ||

|---|---|---|---|

| PLADTR | |||

| Special-grade acrylic pressure-sensitive adhesive | General acrylic pressure-sensitive adhesive (comparative reference value) | ||

| Adhesive strength (N) | Normal | 11 | 11 |

| *Oil surface | 9 | 3 | |

*Oil surface: Measured 2 hours after applying salad oil to SUS board using cotton wool

Test method: 180° peeling test (adhesion of PET film 25 µm thick and 25 mm wide to SUS304 plate)

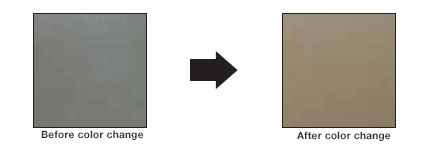

Discoloration of Urethane

Urethane tends to discolor and turn yellow over the course of time.

Discoloration is particularly noticeable in antistatic urethane (gray color), but this does not

affect its physical properties or characteristics.

The process of discoloration over time is shown below. Carefully consider this before

using.

- Discoloration of antistatic urethane over time

White rubber may also turn yellow over the course of time. Be sure to thoroughly understand this tendency before using urethane.