(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Metallic Plate Properties

Comparison of Metallic Plate Material Properties

*The property values below are standard and not guaranteed values.

| Type | Material symbol | Heat treatment (°C) | Representative values of mechanical properties | Representative values of physical properties | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Tensile strength (N/mm^2) | Proof strength (N/mm^2) | Stretch | Hardness | Specific gravity (at 20°C) (g/cm^3) | Conductivity (20°C) IACS |

Thermal conductivity (at 20°C) (CGS) |

Linear expansion coefficient (20-100°C) (× 10-6/°C) | ||||

| Structural steel | SS400 | − | 400~510 | 215 or more | 21% or more | − | 7.87 | − | − | 11.7 | |

| Carbon steel | S50C | Normalizing | 810-860 air cooling | 610 or more | 365 or more | 18% or more | 179~235HB | 7.87 | − | − | 11.7 |

| Annealing | Approx. 800 furnace cooling | − | − | − | 143~187HB | ||||||

| Hardening | 810-860 water cooling | 740 or more | 540 or more | 15% or more | 212~277HB | ||||||

| Tempering | 550-650 rapid cooling | ||||||||||

| S55CN | Normalizing | (at the time of delivery) | 700 or more | 370 or more | 25% or more | 210HB | 7.87 | − | − | 11.7 | |

| Hardening | 850 oil cooling | 810 or more | 540 or more | 25% or more | 250HB | ||||||

| Tempering | 600 air cooling | ||||||||||

| Tool steel | SKS93 | Hardening | 820 oil cooling | − | − | − | 63 HRC or more | 7.87 | − | − | 11.7 |

| Tempering | 180 air cooling | ||||||||||

| SKS3 | Hardening | 800-850 oil cooling | − | − | − | 58~63HRC | 7.85 | − | 0.083 | 12.2 | |

| Tempering | 150-200 air cooling | ||||||||||

| SKD11 | Hardening | 1,000-1,050 air cooling | − | − | − | 58~63HRC | 7.80 | − | 0.070 | 12.0 | |

| Tempering | 150-200 air cooling | ||||||||||

| DC53 | Hardening | 1,020-1,040 air cooling | − | − | − | 56~63HRC | 7.87 | − | 0.057 | 12.2 | |

| Tempering | 180-200 air cooling | ||||||||||

| Stainless steel | SUS303 | Solid solution heat treatment | 1,010-1,150 rapid cooling | 520 or more | 205 or more | 40% or more | 187 HB or less | 7.93 | − | 0.039 | 17.3 |

| SUS304 | Solid solution heat treatment | 1,010-1,150 rapid cooling | 520 or more | 205 or more | 40% or more | 187 HB or less | 7.93 | − | 0.039 | 17.3 | |

| SUS316 | Solid solution heat treatment | 1,010-1,150 rapid cooling | 520 or more | 205 or more | 40% or more | 187 HB or less | 7.98 | − | 0.039 | 15.9 | |

| SUS430 | Annealing | 780-850 air cooling | 450 or more | 205 or more | 22% or more | 183 HB or more | 7.70 | − | 0.063 | 10.4 | |

| SUS440C | Hardening | 1010–1070 oil cooling | − | − | − | 58 HRC or more | 7.70 | − | 0.058 | 10.2 | |

| Tempering | 100-180 air cooling | ||||||||||

| Pre-hardened steel | G-STAR | − | 1060 | 855 | 16% | 33~37HRC | 7.78 | − | 0.060 | 10.3 | |

| PX5 | − | 990 | 880 | 20% | 30~33HRC | 7.85 | − | 0.101 | 12.7 | ||

| NAK55 | − | 1255 | 981 | 15% | 37~43HRC | 7.80 | − | 0.093 | 12.5 | ||

| Aluminum alloy | A5052P-H112 | − | 225 | 125 | 18% | 65HB | 2.68 | 35% | 0.33 | 23.8 | |

| A5052P-H112 (Precision rolled products) | − | 215 | 120 | 21% | 58HB | 2.68 | 35% | 0.33 | 23.8 | ||

| A2017P-T351 | − | 390 | 250 | 13% | 105HB | 2.79 | 34% | 0.32 | 23.6 | ||

| ANP79 | − | 560 | 500 | 12% | 165HB | 2.77 | 32% | 0.31 | 22.1 | ||

| A7075P-T651 | − | 550 | 490 | 12% | 160HB | 2.80 | 33% | 0.31 | 23.6 | ||

| Wrought copper and copper alloy | Tough-pitch copper C1100P | − | 215~275 | 49~343 | 25% or more | 87 HB or less | 8.89 | 97% or more | 0.93 | 16.8 | |

| Oxygen-free copper C1020P | − | 245~315 | 49~343 | 15% or more | 112 HB or less | 8.89 | 97% or more | 0.93 | 16.8 | ||

| Chrome copper Z3234 | − | 380 or more | − | 15% or more | 125HB | 8.89 | 70% or greater | 0.8 | − | ||

| Brass plate C2801P | − | 355~440 | − | 25% or more | − | 8.43 | − | − | − | ||

CGS:Cal/℃・cm・sec

Aluminum Plate Comparison

| Type | Material symbol | Model | General corrosion resistance | Weldability (argon) | Machinability | Brazing | Anodizing |

|---|---|---|---|---|---|---|---|

| Al-Mg alloy | A5052P-H112 |

ALN□ PN□□□ |

Good | Good | Normal | Normal | Good |

|

A5052P-H112 (Precision rolled products) |

ALA□ | Good | Good | Normal | Normal | Good | |

|

Al-Cu alloy (duralumin) |

A2017P-T351 |

ALD□ ALJ PD□□□ |

Poor | Impractical | Good | Poor | Poor |

|

Al-Zn-Mg alloy (super duralumin) |

ANP79 | P79□□□ | Poor | Poor | Very good | Poor | Poor |

| A7075P-T651 |

ALP□ PP□□□ |

Poor | Impractical | Good | Poor | Poor |

The high precision plate, ALA□ / ANP79 Plate P79□□□ eliminates internal stresses during

rolling.

The low residual stresses result in less processing distortion than general A5052/A7075

materials.

Annealed SS400 Material

Features

- SS400 is annealed to reduce internal stress.

- It is resistant to processing distortion and is recommended as a countermeasure against warpage during machining.

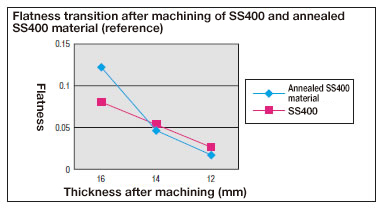

The left graph shows that the annealed material has a more stable flatness variation after machining than the normal SS400.

[Testing method] Milling machine was performed on the above two materials (155 × 155 × 16 mm), 2 mm per pass, and flatness was measured (3-D measuring instrument).

S55CN

Features

- S55C is normalized to reduce internal stress.

- Adding free-machining ingredients improves machinability.

- Superior mechanical strength compared to S50C.

SUS303, 304 Annealed Materials, SUS430 Materials

Features

- Stress relief heat treatment is applied to SUS303 and 304 to reduce internal stress.

- This stainless steel material is resistant to machining distortion and is recommended as a countermeasure against warping during machining.

- Corrosion resistance is slightly inferior to SUS303 and 304.

SUS430

Features

- It is ferrite-based stainless steel with high corrosion resistance.

- The magnetism allows simultaneous polishing.

- It has no hardening hardenability.

ANP79

Features

- This 7000 series material has the inherent lightness of aluminum.

- It has a hardness exceeding 15C of steel, and its machinability is at least 10 times higher than that of iron.

- Compared to 7075 materials, it is not inferior in strength, has higher uniformity of mechanical properties, and reduces internal stress.