(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Please be informed of our operating hours during the Chinese New Year Holidays. More details.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Gas spring

About gas springs

High-pressure gas (nonflammable nitrogen gas) is enclosed in a sealed cylinder, and the reaction force of this gas is used as a spring. These gas springs are small in size, yet provide a small spring constant with a large initial load, so they are widely used in machines, furniture, automobiles, office equipment, etc.

Features

- Provides a large spring force (reaction force) despite being compact and lightweight.

- The spring force (reaction force) is almost constant over the long stroke.

- It can be designed and used for a wide range of applications.

How to select the right gas spring

-

1.

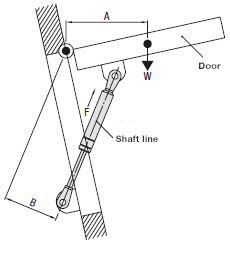

Find the required reaction force (F) using the following formula.

F= W×A

−−−

B- F

- : Required reaction force (at maximum length)

- W

- : Weight of door, etc.

- A

- : Horizontal distance from the fulcrum (hinge of a door, etc.) to the center of gravity

- B

- : Distance of the perpendicular line from the fulcrum (hinge of a door, etc.) to the shaft line of the gas spring

- 2. The reaction force of the gas spring to select should be at least F x 1.1.

- 3. If the required reaction force (F x 1.1) is greater than the reaction force at the maximum length of the gas spring - ( ) mm, use two or more springs.

- 4. The reaction force is designed for a temperature of 20°C. The repulsive force increases or decreases with a change in temperature.

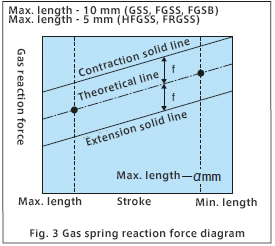

The gas reaction force is indicated in the catalog at the maximum length - 10 (5) mm and maximum length - α mm. In general, the gas reaction force varies proportionally, so when determining the repulsive force at the required stroke, connect these two points with a straight line as shown in Figure 3, read the point of the stroke of interest, and estimate the force.

f = Internal sliding friction (theoretical value x 0.1)

Precautions for use (standard for GSS, FGSS, HFGSS, and FRGSS)

-

Please pay attention to the temperature of the gas spring during use and storage.

(Product temperature range: GSS, FGSS: -20°C to 60°C / HFGSS: -20°C to 80°C / FRGSS: -30°C to 80°C) - Gas reaction force varies slightly by product.

- Gas reaction force varies according to temperature.

- Reaction force may decrease due to the operating environment, frequency of use, etc. Replace the spring when it no longer meets the required reaction force.

- Do not store or use springs in an environment where the rod may rust or in a chemical atmosphere. Also, do not paint gas springs.

- Do not damage the cylinder rod. Do not apply flexural load, torsion, or other forces.

- Do not extend the gas spring beyond its maximum length. Use within a range where a margin of about 10 mm remains from the stroke end even at the maximum stroke (compression). Also, do not extend or retract at a rapid speed (1 m/s or more, as a guide).

- Use the GSS type with the cylinder end up and the rod end down, so that the oil inside protects the rubber seal. Do not use the GSS and FRGSS at an angle of 60° or more. FGSS and HFGSS types have no restrictions on the angle of use, but are recommended to be used with the rod down.

Features of free swivel-type gas springs (FGSS and FGSB)

About free swivel-type gas springs

- 1. Nonflammable nitrogen gas is sealed in gas chamber C, and a free piston enables the reaction force of the gas to be used as a spring.

- 2. Gas chamber C always has a repulsive force in the direction of elongation because oil chamber AB is pressurized. The magnitude of the repulsive force is therefore determined by the internal pressure of gas chamber C.

- 3. When the rod moves out of position, the oil in chamber AB passes through the orifice hole in the piston.

- 4. The volume change of the rod in the cylinder is adjusted by the change in gas chamber C.