(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

Design of chain drive mechanism 4

Mounting method

(A) Shaft position

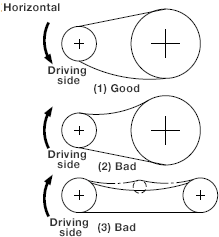

Horizontal

Even if positioned so that both shafts are horizontal, it must be taken into account depending on the rotation direction of the shaft. The examples (2) and (3) in the figures show the separation between the sprocket teeth and the chain if the chain is stretched and so it may not bit properly. In (3), please use an idler since the upper and lower chains may touch.

(Either change the rotation direction or use an idler.)

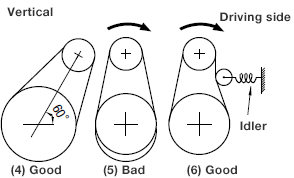

Vertical

If the chain stretches, it deflects as in (5), and where small sprockets are used on the underside, the chain may come off. For that reason, use it at an angle of less than 60° as in (4). Where it must be used vertically for mechanism or space reasons, it is recommended that a big sprocket is put on the underside, and an idler etc. used on the outside or the inside as in (6).

(B) Deflection

Deflection should be around 4% for general wheel-base distances, and around 2% in the following cases.

a. For vertical drive or close to it

b. When wheel-base distance is greater than 1m

c. When frequent start-stop is necessary for heavy duty

d. When reverse rotation is required

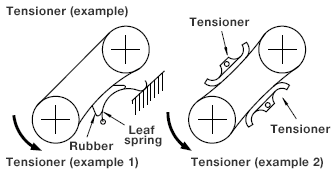

(C) For variable loads

If a tensioner is attached on the tension side or the deflection side, the an initial tension applied in advance, vibration of the chain on startup can be eliminated and noise decreased.

Lubrication

Lubrication is most important for the roller chain, and poor lubrication will impact the lifespan of the chain. In particular in recent years it is often used at high speed so an efficient lubrication method must be used.

Effect of lubricant oil

When oil is poured into the gaps between pins, bushings and rollers, it forms an oil membrane. This oil membrane suppresses the friction of parts, working as a cushion against shocks. It also has a cooling effect that removes the heat generated by the chain. In general, a good quality mineral oil should be used for the roller chain lubricant oil.

| Lubrication format | A・B | C | ||||||

|---|---|---|---|---|---|---|---|---|

| -10~0 | 0~40 | 40~50 | 50~60 | -10~0 | 0~40 | 40~50 | 50~60 | |

| CHE25~50 | SAE10 | SAE20 | SAE30 | SAE40 | SAE10 | SAE20 | SAE30 | SAE40 |

| CHE60~80 | SAE20 | SAE30 | SAE40 | SAE50 | ||||

| Lubrication type | Name and method | Lubrication interval and lubricant amount | Cautions |

|---|---|---|---|

| A |

|

In general, do the oiling once per day at a minimum, with regular oiling by an oiler or brush. | Pour the oil while slowly rotating the chain, and do this 3 - 4 times evenly for the whole length. Note to take care that hands and clothing are not caught in the chain during oiling. Also excess oil may splatter when restarting after oiling, so please take care. |

|

Please feed lubricant at around 5 - 20 drops per minute. | In this case, a simple casing is recommended so that the oil does not splatter. | |

| B |

|

The chain should be submerged in the oil around 10mm below the oil surface. | Of course, a case that does not leak oil should be used, and also the case should be completely cleaned of dirt and other contaminants before it is used for the first time. Please be careful that the oil amount does not increase. |

|

Using the method of pouring oil on the chain via a rotating plate, set the depth of rotating plate soaked in oil to 20mm, and the peripheral speed to more than 200m/minute. | ||

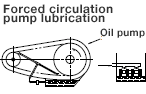

| C |

|

The amount of oil supplied must be set appropriately so that an abnormal heat is not generated. | Of course, a case that does not leak oil should be used, and also the case should be completely cleaned of dirt and other contaminants before it is used for the first time. |