(!)Due to

Microsoft's end of support for Internet Explorer 11 on 15/06/2022, this site does not support the recommended

environment.

Instead, please kindly use other browsers like Google Chrome, Microsoft Edge or Mozilla

Firefox.

- [Temporary Suspension of Order Acceptance for the Middle East] Due to suspension of air transport & courier services to the Middle East region, we regret to inform that we will temporarily stop accepting order(s) until further notice. Thank you for your understanding.

- Notice of End of Sales for Economy Series Pneumatic Equipment Category. More details.

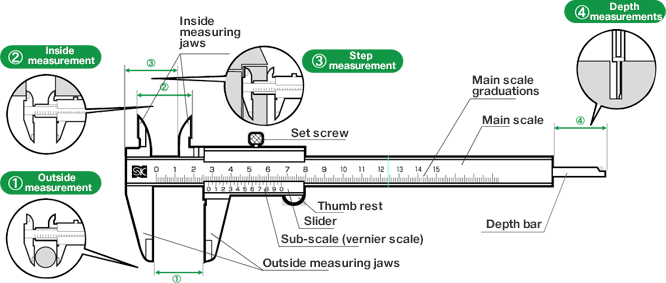

Correct Use of Vernier Calipers

Here are explanations on the correct method of taking measurements using a vernier caliper, an

essential tool in the machining workplace, and recommended vernier caliper products.

A straightforward explanation of indispensable maintenance and inspection methods for measuring

tools is also provided here.

- Vernier caliper basics

- Correct technique for taking measurements using vernier calipers

- Maintenance/inspection

- Recommended products

Vernier caliper basics

Vernier calipers can be used to take inside and outside measurements, as well as to measure

steps and depth. They are one of the most common measuring tools in the machining

workplace.

Here are the names of the various parts and the shapes that they can be used to measure.

Types of vernier calipers

In addition to standard styles, there are various other types of vernier calipers that are

adapted to measure different shapes and features, such as narrow grooves, hole pitch, pipe

thickness and so on.

Select the vernier calipers that are most suitable for the shape and features of the item

measured.

● For pipes

● Hole pitch

● Points

● Inside

Source: Niigata Seiki Co., Ltd.

Correct technique for taking measurements using vernier calipers

How to apply vernier calipers to the item measured

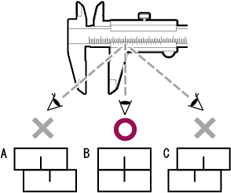

■ When measuring a cylindrical object

Apply the jaws of the vernier calipers so that they are at right angles to the axis of the

cylinder.

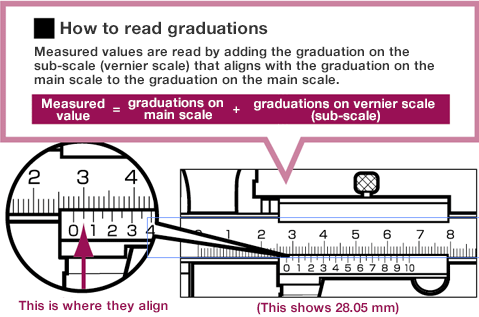

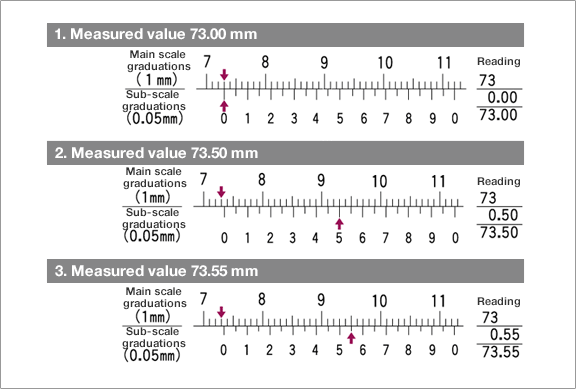

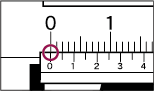

How to read graduations (analog vernier calipers)

How to read graduations

The measured value is read from a combination of the graduations on the main scale and the sub-scale (vernier scale). The graduations in the diagram below should be read as 73.000 mm in Example 1, 73.50 mm in Example 2, and 73.55 mm in Example 3.

Source: Niigata Seiki Co., Ltd.

Maintenance/inspection

Here is some information of the main components of daily inspections aimed at maintaining the

accuracy of your vernier calipers.

Check whether your vernier calipers are capable of accurate measurements.

Daily inspection checklist

1. Check whether there is any unevenness in the movement of the slider

If there is unevenness, use an oil stone to dress the main scale.

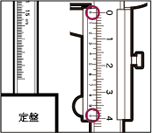

2. Check whether the 0 point is aligned

The 0 and 10 graduations on the vernier scale must be aligned with the graduations on the main scale.

3. Check the jaws

Check whether any light is visible through the outside jaws when they are closed and held up to a source of illumination.

4. Check depth

Place the vernier calipers vertically on a reference surface, and similarly to 2., check whether the 0 and 10 graduations are aligned with those on the main scale.

Source: Niigata Seiki Co., Ltd.

![[Kanon] Flat Head Caliper E-PITA](/tech-info/categories/quality_control/qc01/img/a0374/a0374_13.png)

![[Kanon] Centerline Caliper E-RM-J](/tech-info/categories/quality_control/qc01/img/a0374/a0374_15.png)

![[Kanon] Vernier Caliper for Inside Measurement E-ICM-J](/tech-info/categories/quality_control/qc01/img/a0374/a0374_16.png)

![[Kanon] Long Jaw Caliper E-LSM](/tech-info/categories/quality_control/qc01/img/a0374/a0374_17.png)

![[Kanon] Caliper with Curre Jaw RA](/tech-info/categories/quality_control/qc01/img/a0374/a0374_19.png)